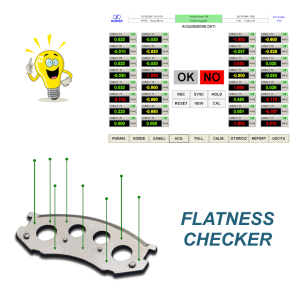

Flatness measurement on blanked parts

RFID traceability of waste paper bales

Control of defects on continuous products

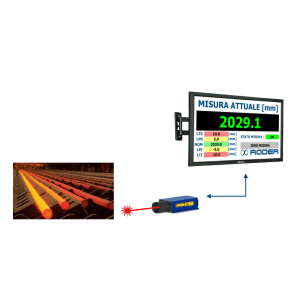

Measurement of the position of beams and pipes in line of position

Bending measurement on tube and profile benders

Application Kit for the use of LDM42 industrial LASER distance meters

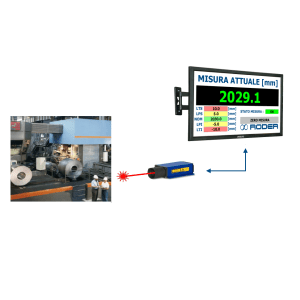

Use of LASER distance meters for position and distance measurements

DM2 series LED illuminators for ROBOT guide

Radius measurement on curved furniture products

LED backlighting for vision systems

Digital radius and diameter gauge DIACHECK-CT series

Measurement of the position of logs and wooden panels

Measurement of the radius of curvature with digital archimeters

Measurement of the torque and tearing of the cap of bottles, bottles, jars both in screwing and unscrewing

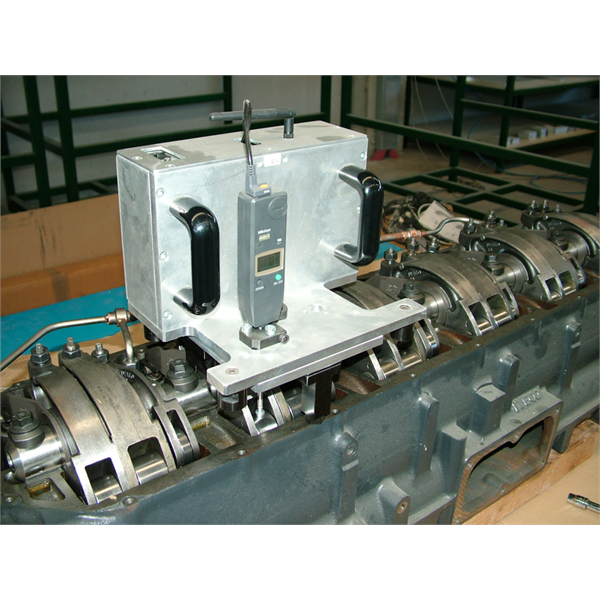

Flatness measurement with multi-dimension control units and LVDT linear transducers

DL1 series LED illuminators for vision systems and optical inspection benches

Dimensional checks with multi-quota control units and LVDT linear transducers

Artificial vision systems for the control of defects on continuous products in the production line

Systems for measuring the position, displacement and deformation of large structures

LASER scanner for dimensional and geometric control of continuous products in the production line

Level measurement in tanks, silos or large containers with level display on remote monitors

Stroboscopes for speed measurement and preventive maintenance

LVDT linear transducers for dimensional and geometric control

DIACHECK measuring instruments for internal diameter measurements

SB-1000 series LASER micrometers for non-contact diameter and width measurement

Monitoring of distances, positions, lengths and depths with LASER distance meters and visualization on giant displays for the metallurgical and steel industry

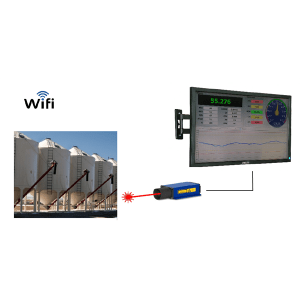

Level monitoring with LASER distance meters and visualization on giant displays

LASER scanner for checking the profile of paper, cardboard and embossed products

Systems for the control of the axial play of crankshafts and pulleys in internal combustion engines