Category: Electronics and electrical engineering applications

-

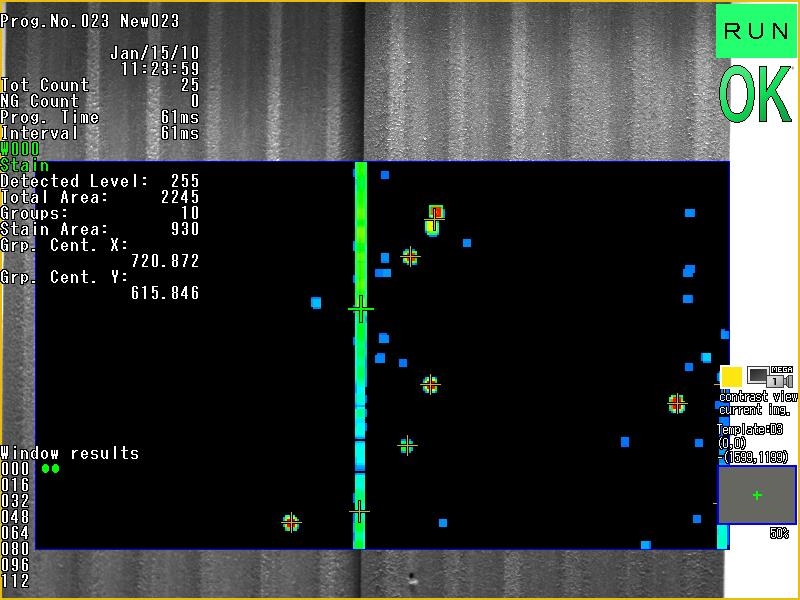

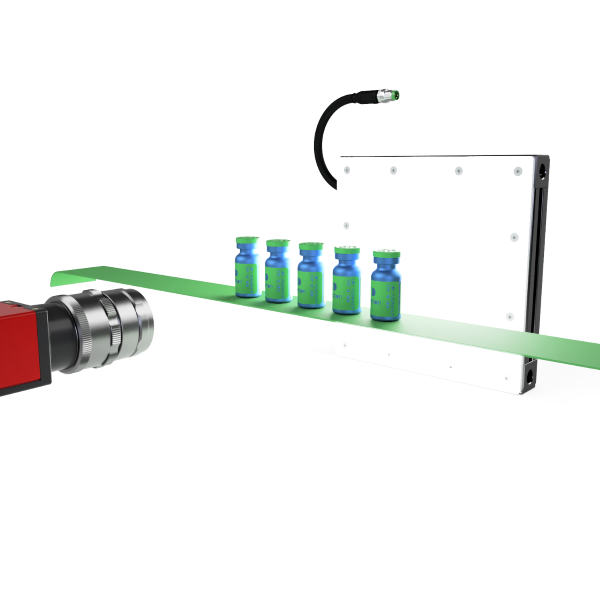

Artificial vision systems for the control of defects on continuous products in the production line

Machine vision is a key technology for Industry 4.0 and the inspection of defects in continuous products on the production line. With the help of vision systems, such as LED illuminators, industrial and linear cameras, image processors and artificial intelligence, greater precision can be achieved in identifying product defects. Systems based…

-

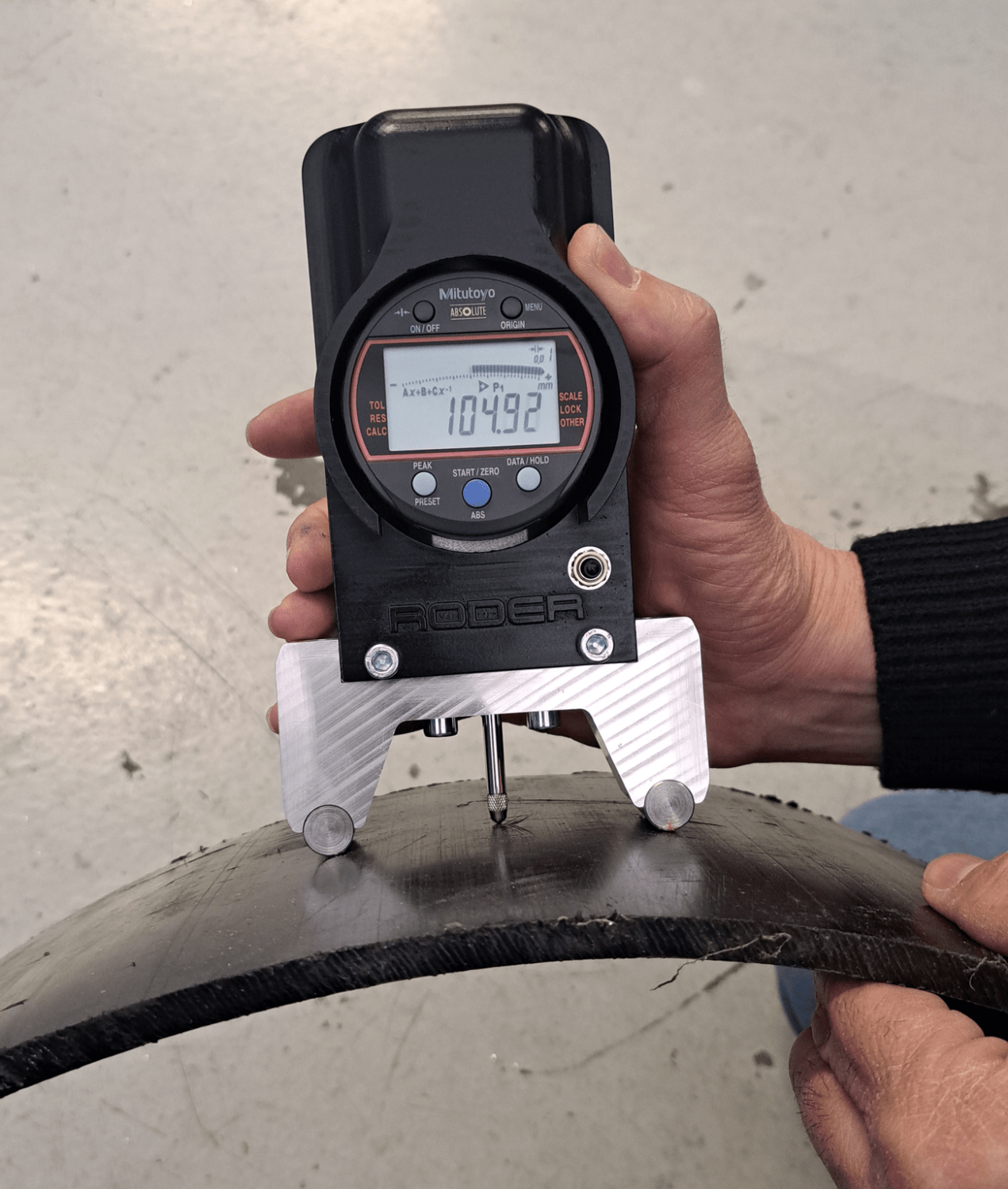

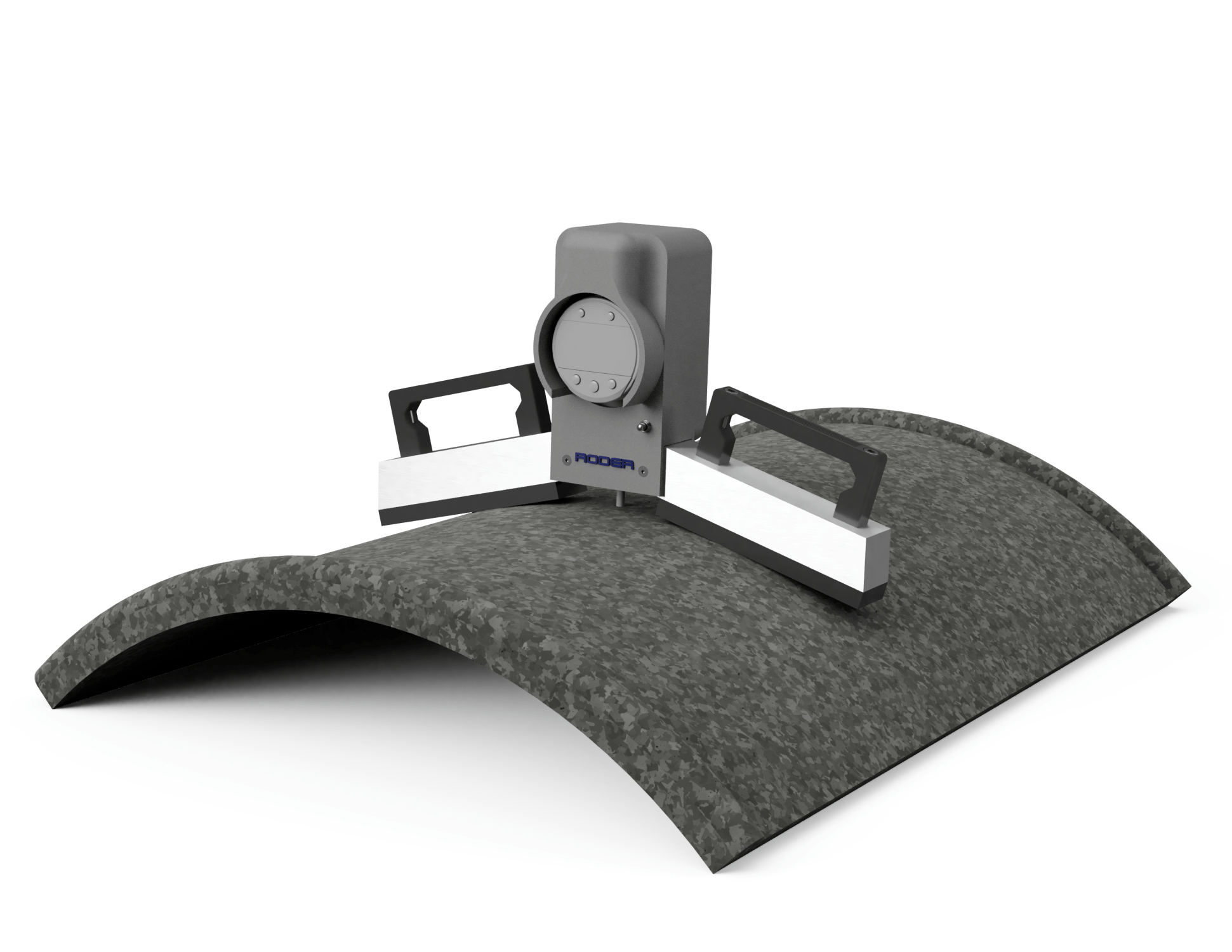

LASER scanner for dimensional and geometric control of continuous products in the production line

Laser scanning systems are a type of inspection technology used in the manufacturing industry to provide an accurate measurement of the shape and dimensions of products. Laser technology offers unrivaled precision in the inspection and measurement of complex contoured products, including 3D profiles. Furthermore, the speed and reliability with which a laser can perform…