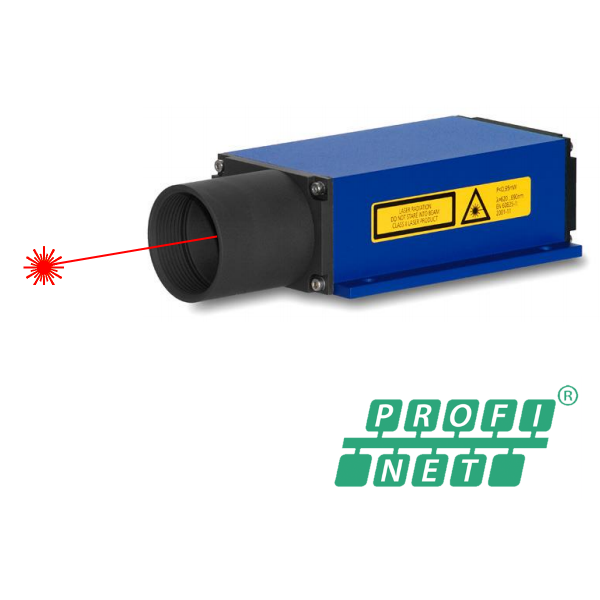

LASER distance meters for industrial applications Non-contact distance measurement in total safety Visible LASER with safety class 2 also suitable for measurements in the presence of an operator Analogue data output, RS232, RS422, Profinet, Profibus, Ethernet. The family of LASER LDM distance meters is composed of a series of optoelectronic distance measurement devices for industrial applications with analogue (from 4 mA to 20 mA) or digital (Ethernet, Profinet, Profibus, RS232, RS422) interface. The LASER distance meters of the LDM series are used for the precise measurement of distances from a few meters up to three kilometers. Distance measurement represents an application…