Tag: laser thickness measurement

-

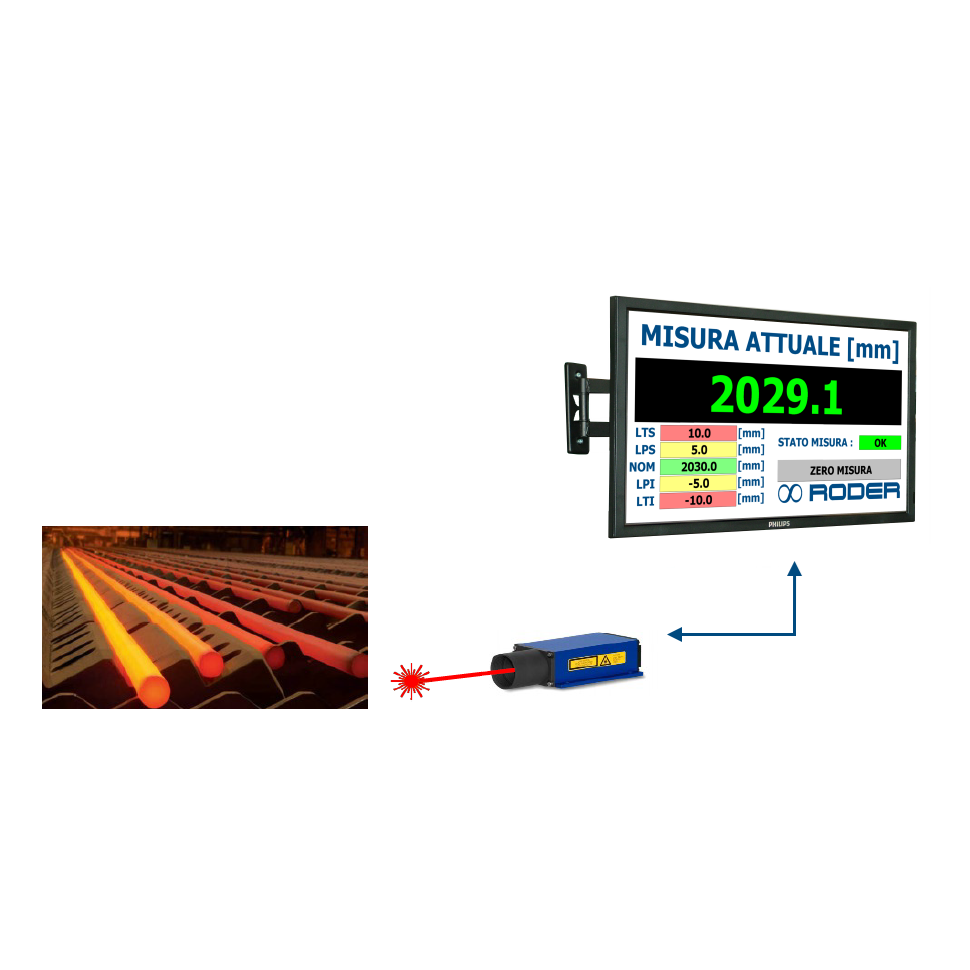

Non-contact thickness measurements on the production line with LASER thickness gauges

LASER thickness gauges for non-contact control of the thickness and width of flat materials. Suitable for measuring the thickness of sheets, strips, boards, profiles and carpets. Non-contact measurement allows you to measure moving objects, even at high speed, or easily deformable materials that with contact measurement techniques…