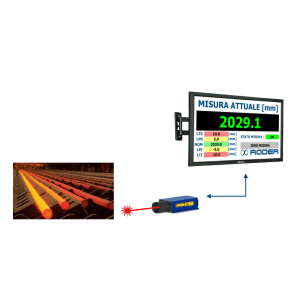

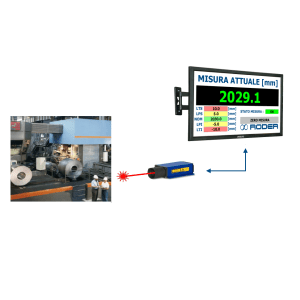

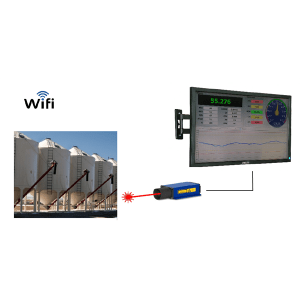

Thanks to the AK1 Kit it is possible to evaluate the performance of the LDM42 industrial LASER distance meters in a very short time and without the help of an installer or software engineer. Simply connect the power socket, position the distance meter in front of the target to be measured and the sensor will immediately show the value on the display. The AK1 Kit was designed to simplify the use of the LDM42 industrial LASER distance meters, making it accessible to everyone, even to unqualified personnel. In manufacturing environments, accuracy in the placement of materials and structures is crucial. Often, using LASER distance meters is the ideal solution, but the installation process…