Tag: artificial vision

-

DL1 series LED illuminators for vision systems and optical inspection benches

LED lighting is a technology that is becoming increasingly important in industrial vision systems. LED lights are very efficient, economical and reliable, and can be used to illuminate specific areas in an environment with precision. Furthermore, LEDs are more long-lasting than other traditional light sources, so…

-

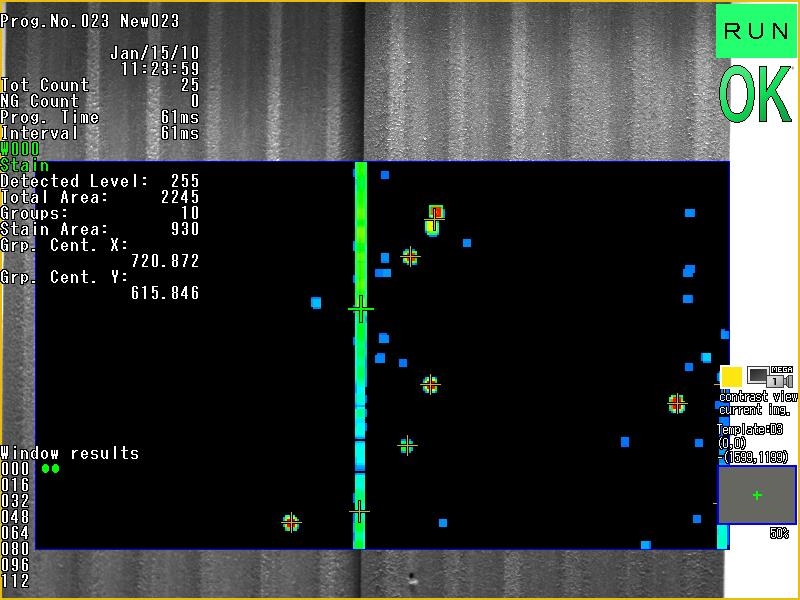

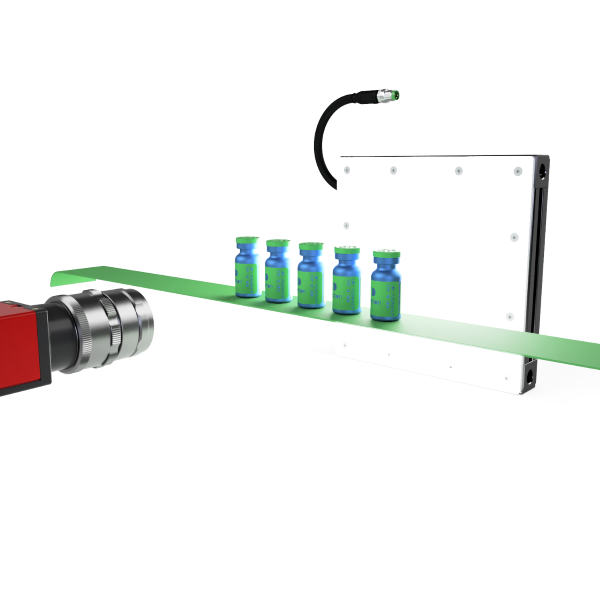

Artificial vision systems for quality control on the production line

Artificial vision systems for the visual and dimensional control of industrial products. The PCL2315 control station is equipped with a latest generation industrial controller capable of processing the images acquired in real time, generating the control response in a few milliseconds.

-

Visual inspection of miniaturized components with artificial vision systems and compact LED illuminators

Detection of defects and dimensional characteristics on small parts using artificial vision systems and image processing algorithms. Use of compact LED illuminators with continuous or pulsed operating modes. Real-time detection of the presence of defective parts or parts with aesthetic characteristics that do not comply with the specifications…

-

DL3 mini series LED illuminators for vision systems with industrial cameras

LED illuminators for direct lighting applications in industrial camera-based machine vision systems. Can also be installed on manual optical test benches, testing systems or manual selection benches. Flat profile for special applications suitable for System Integrators and OEMs. Cable with M8 industrial connector, anodized aluminum container. RODER SRL…

-

DL2 series LED illuminators for vision systems with industrial cameras

LED illuminators for direct lighting applications in industrial camera-based machine vision systems. Can also be installed on manual optical test benches, testing systems or manual selection benches. Flat profile for special applications suitable for System Integrators and OEMs. Cable with M8 industrial connector, anodized aluminum container and driver…

-

RIMAS - Robotic system for inspection, measurement and assembly of mechanical parts

Robotic system for the automatic inspection of mechanical parts in the production line. Used for the assembly of mechanical parts and for non-destructive quality control. Wide range of measurements and usable technologies (cameras, laser scanners, eddy current, torque cells, dynamometers, laser micrometers, laser marking) High customization and integration into the production line…