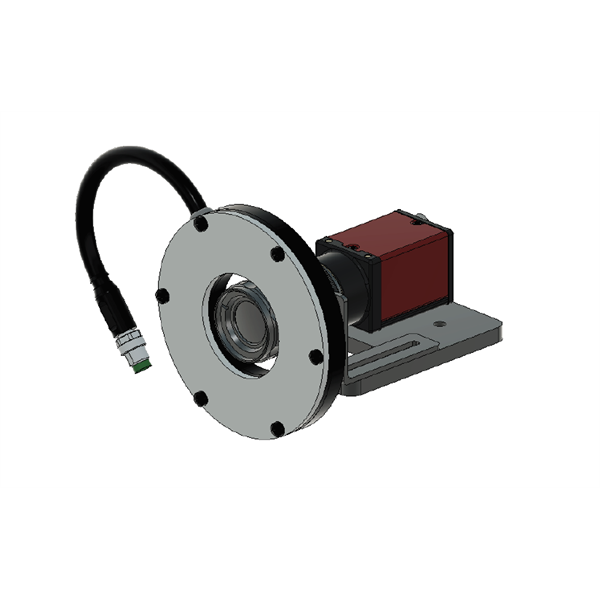

Cap torque meters for measuring the tightening torque, both during screwing and unscrewing, of bottle caps, barrels, containers, jars, bottles, containers and cans. Cap torque meters for measuring the tightening torque, both during screwing and unscrewing, of bottle caps, barrels, containers, jars, bottles, containers and cans. The CAP-TT01 series cap torque transducers are designed to measure cap tightening and cap removal torque up to 11,5 Nm (100 lbFin). Adjustable stands effectively hold a wide range of shapes and sizes in place…