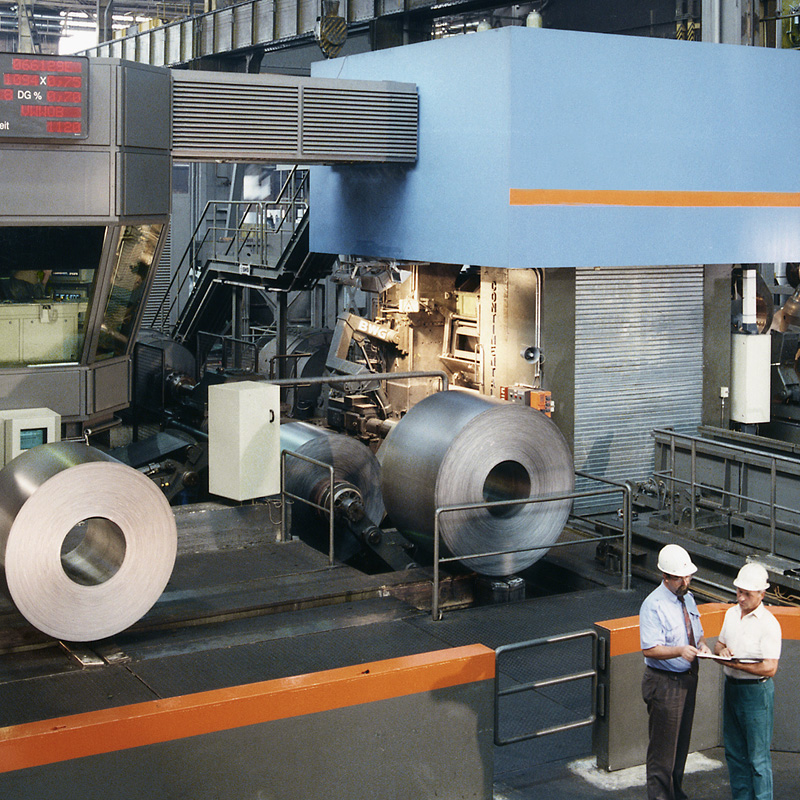

Category: Mining sector application

-

Systems for measuring the position, displacement and deformation of large structures

Systems for measuring the position, displacement and deformation of large structures can be extremely complex. Laser dimensional inspection technology offers a simple and effective way to address these issues. Laser distance meters are devices that use a light beam to measure the distance between two points with precision and accuracy…