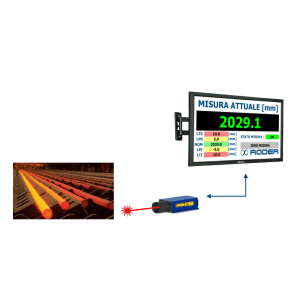

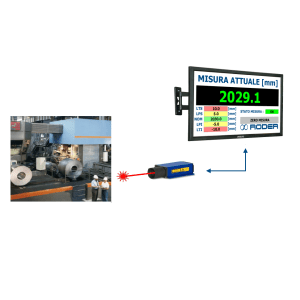

The VISIONCHECK-AI system allows the control of defects on continuous products with the use of artificial intelligence VISIONCHECK-AI is an intelligent inspection system dedicated to the control of defects on continuous products, based on artificial intelligence algorithms, a product developed by RODER LLC. The system uses advanced vision technology to detect and classify defects on continuous products with unprecedented accuracy and precision. The system is suitable for a wide range of industries, including metals, automotive, aerospace and electronics. With its unique combination of accuracy and convenience, VISIONCHECK-AI offers a truly versatile solution for…