Category: Metal and semi-finished sector applications

-

Flatness measurement on blanked parts

Measurement of flatness of parts made with a fine blanking, molding or laser cutting process. The flatness measurement is performed with multi-dimension systems capable of calculating total flatness, partial flatness or possibly dimensional dimensions.

-

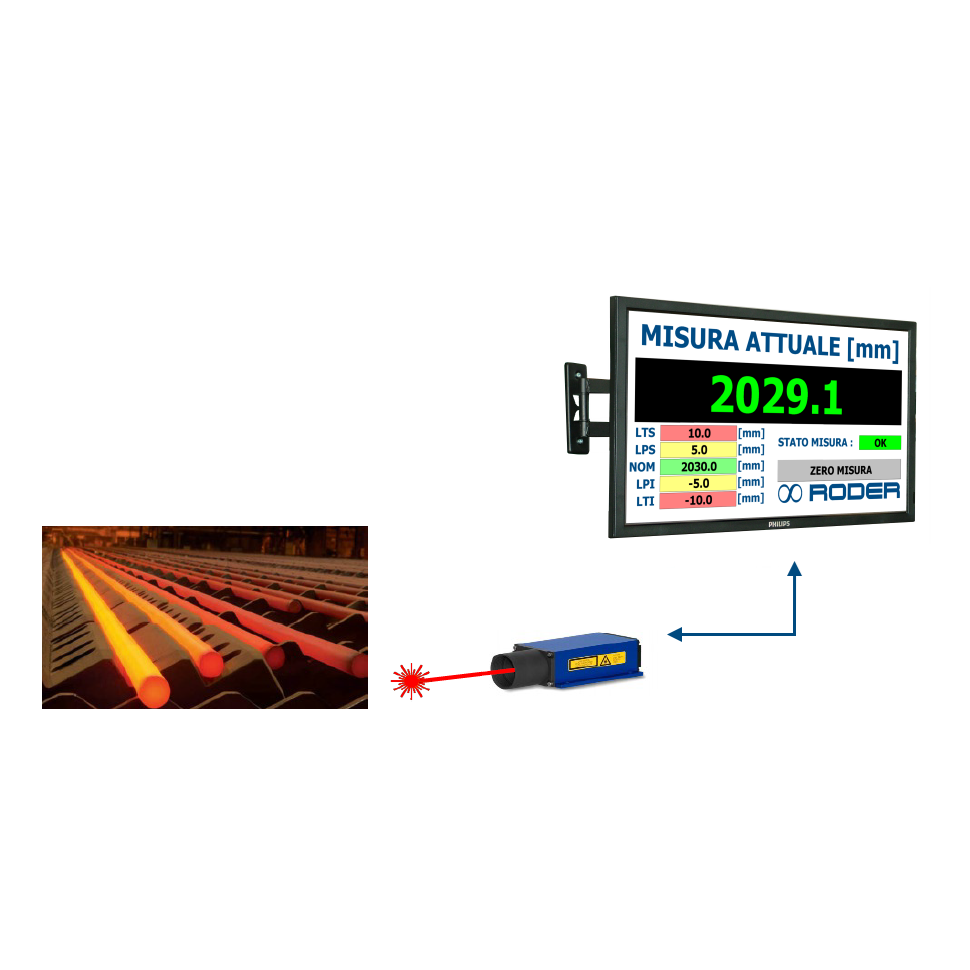

Measurement of the position of beams and pipes in line of position

Laser technology is essential for industrial measurement due to its precision and ease of use. RODER laser distance meters offer a complete and high-performance solution, optimizing the application in professional contexts. The kit allows immediate operation, integration with remote monitoring and generation of detailed reports, improving work efficiency and precision.

-

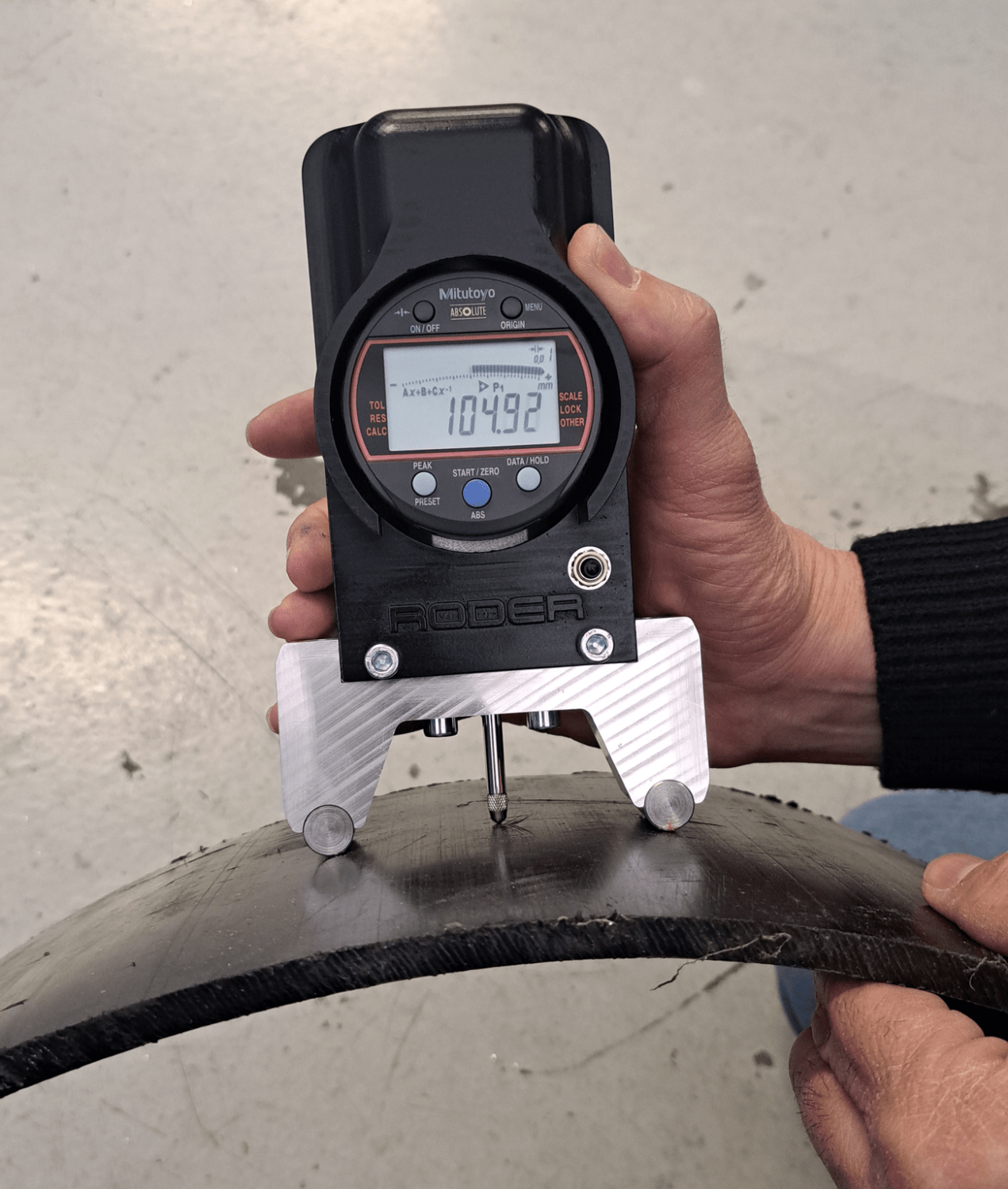

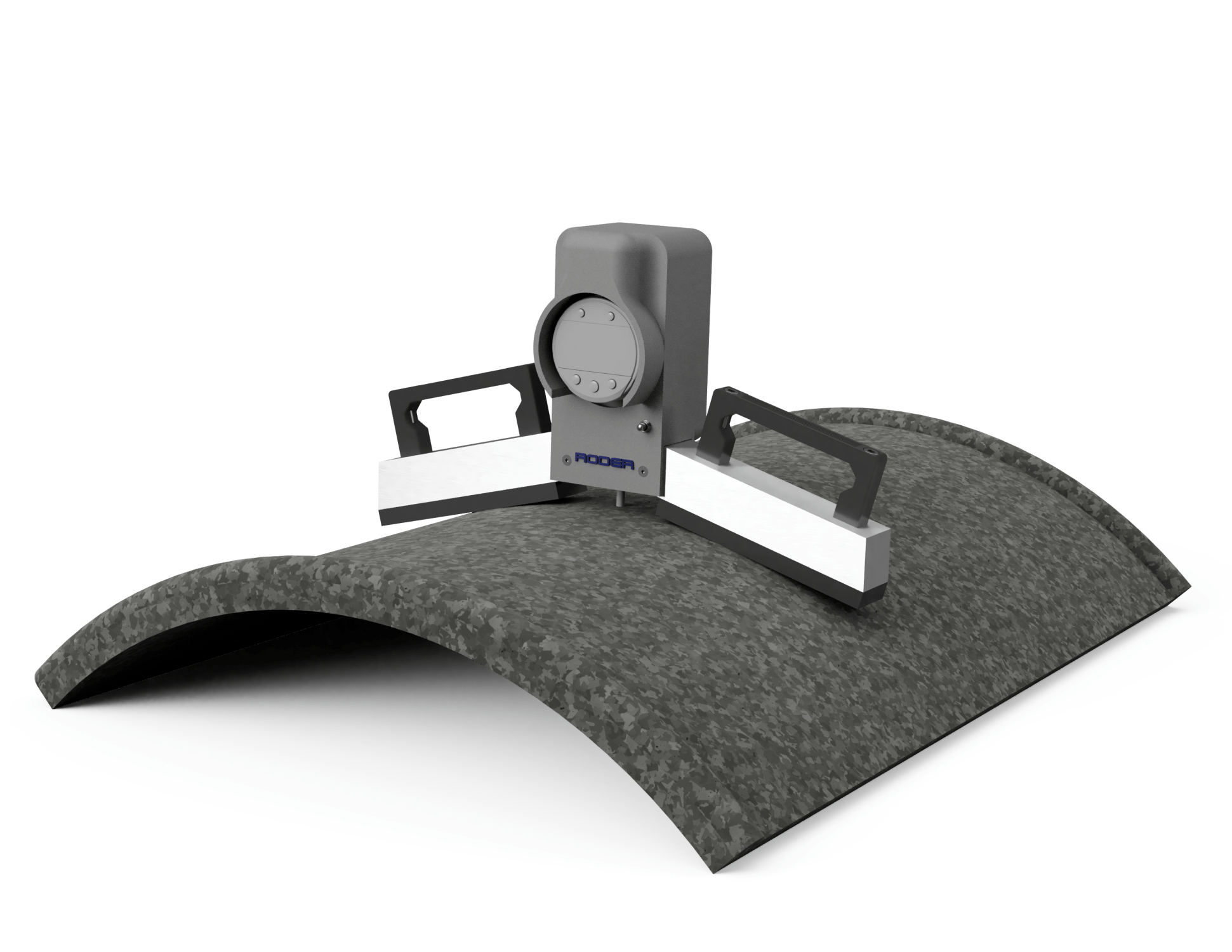

Bending measurement on tube and profile benders

The DIACHECK-CT series digital archmeter allows direct and instantaneous reading of internal or external radii or diameters in a range between 100 and 10000 mm. The measurement is easy and immediate. It is sufficient to place the instrument on the object to be measured and the measurement appears instantly on the instrument display.

-

Application Kit for the use of LDM42 industrial LASER distance meters

The AK1 Kit represents an effective and practical solution for the use of industrial LASER distance meters. The product, based on the LASER LDM42 distance meter, is ready to use and does not require any programming or wiring by qualified personnel.

-

Use of LASER distance meters for position and distance measurements

LASER technology establishes itself as a fundamental ally in professional measurement processes, thanks to its precision and ease of use. Today, engineers and specialized technicians can enjoy the potential offered by laser distance meters, cutting-edge tools for accurately detecting distances. RODER has produced a specific application kit that can elevate the experience of using…

-

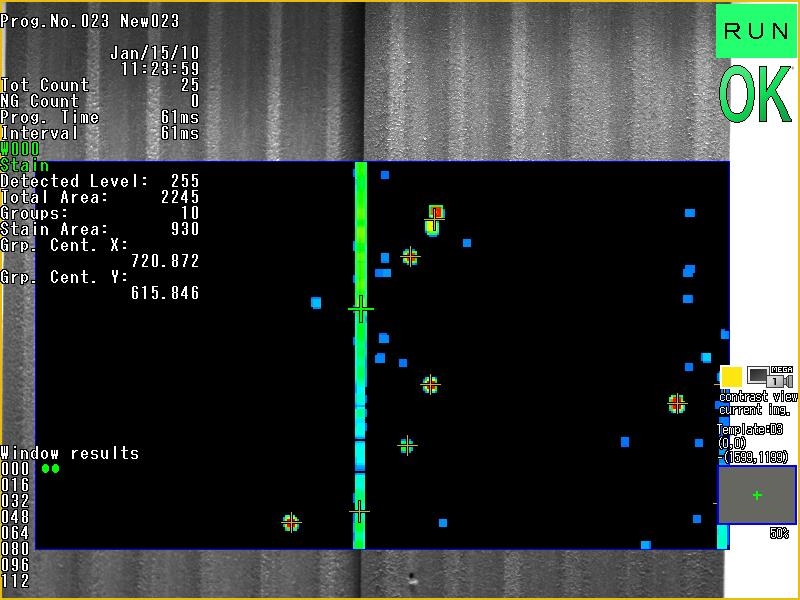

Control of defects on continuous products

The VISIONCHECK-AI system allows the control of defects on continuous products with the use of artificial intelligence. The system is based on deep learning algorithms and neural networks. The analysis is carried out in real time. Learning is based on continuously evolving mathematical models with guided or automatic learning.

-

Measurement of the radius of curvature with digital archimeters

The DIACHECK-CT series digital radius and diameter meter allows direct and instantaneous reading of internal or external radii or diameters in a range between 100 and 10000 mm. The measurement is immediate, just place the instrument on the profile to be measured and the measurement appears on the instrument display.

-

Digital radius and diameter gauge DIACHECK-CT series

The DIACHECK-CT series high-precision digital diameter and radius meter is designed to measure the radius of cylindrical objects such as pipes, profiles and calenders quickly and accurately. This measuring instrument allows the measurement of the radius of curvature or the internal or external diameter of a specific part using the method…

-

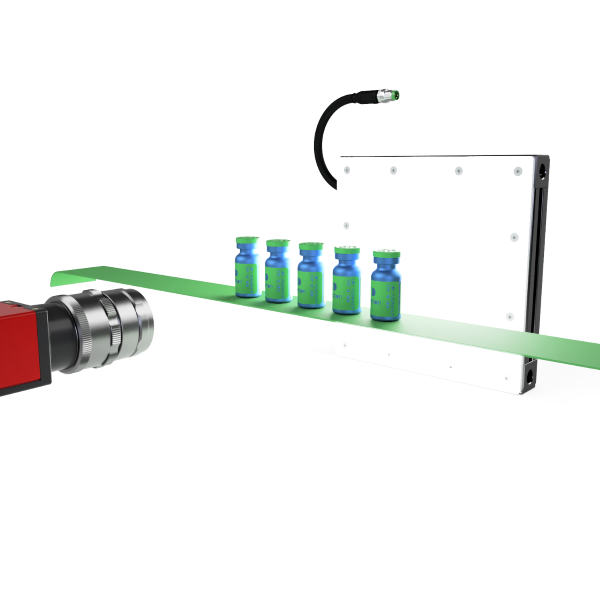

LED backlighting for vision systems

LED backlight systems for industrial automation and machine vision applications. Suitable for vision systems based on the principle of shadow projection. Large illumination area and high uniformity.

-

Radius measurement on curved furniture products

The DIACHECK-CT series digital radius and diameter meter allows direct and instantaneous reading of internal or external radii or diameters.