Control of defects on continuous products

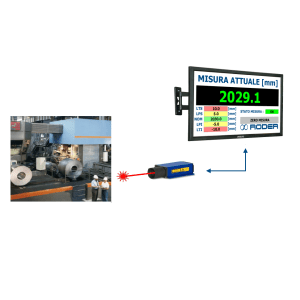

Measurement of the position of beams and pipes in line of position

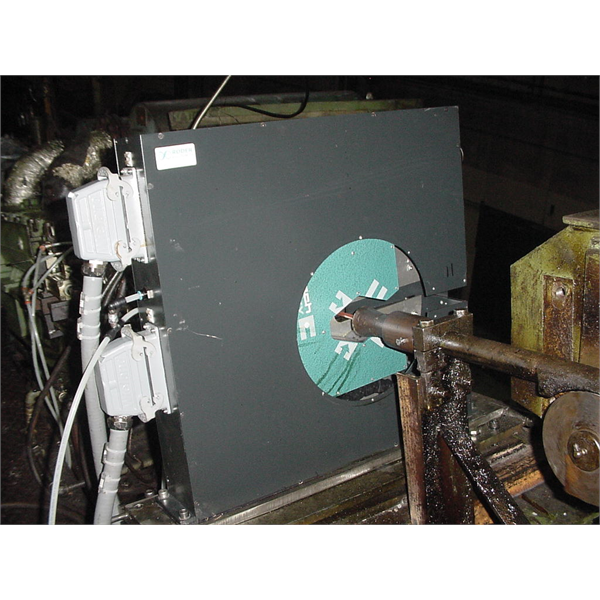

Bending measurement on tube and profile benders

Application Kit for the use of LDM42 industrial LASER distance meters

Use of LASER distance meters for position and distance measurements

Dimensional checks with LASER sensors

Measurement of the radius of curvature with digital archimeters

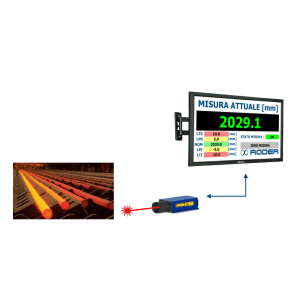

Dimensional controls of metallic materials at high temperatures

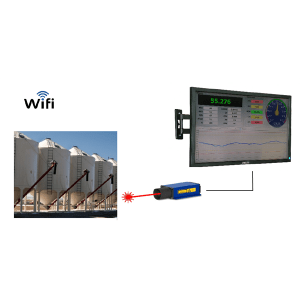

Level measurement in tanks, silos or large containers with level display on remote monitors

Monitoring of distances, positions, lengths and depths with LASER distance meters and visualization on giant displays for the metallurgical and steel industry

Level monitoring with LASER distance meters and visualization on giant displays

Measurement systems and optical profilometers for the measurement of railway profiles

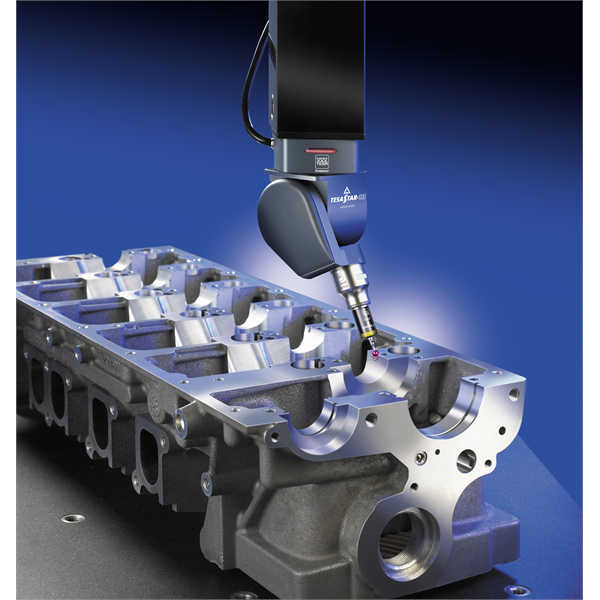

Robotic control islands for automatic hardness control on pins and mechanical parts

Robotic islands for quality control with artificial vision systems

Dimensional control of drawn bars in the production line

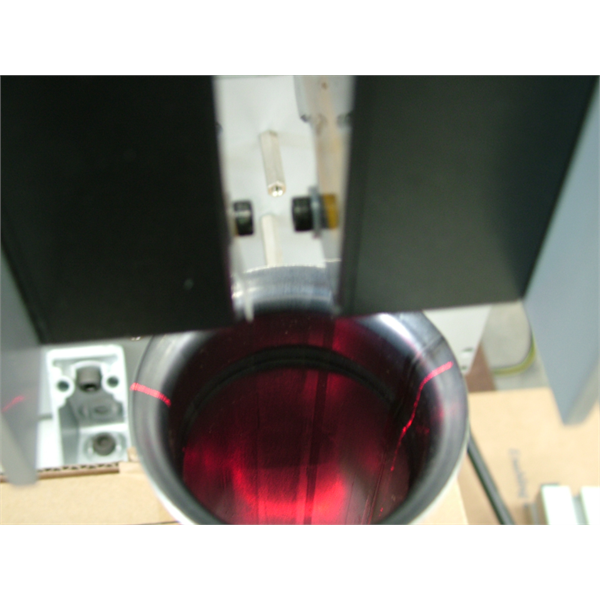

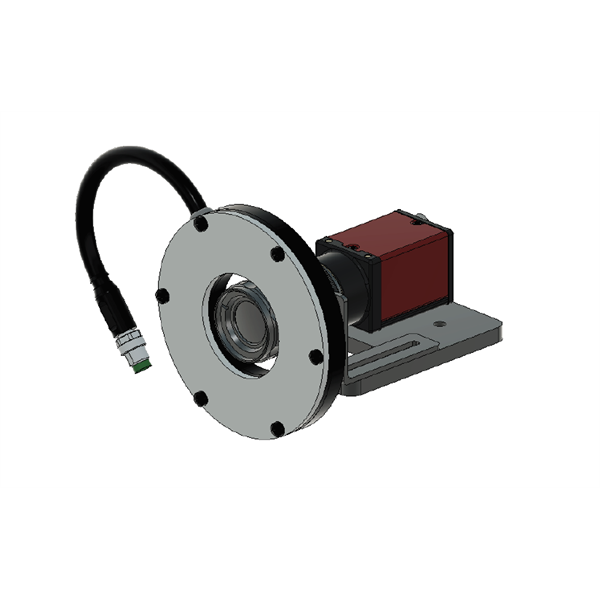

Measurement of diameter and ovality of pipes, wires and cables in the production line

Multidiameter LASER scanner for multi-wire control on drawing, galvanizing and enamelling lines

Measurement of the width of continuous tapes in the production line

Measurement of the thickness and width of metal strips in the production line

Measurement of the deep drawing and flaring profile of pipes and flanges

Special lighting systems for production line vision systems

Systems for traction control on mechanical components and assembled systems

Data acquisition and statistical calculation systems for quality control

Ultrasonic measuring instruments for thickness measurements

Special components for industrial automation, measurement automation and non-destructive control

Artificial vision systems for visual inspection of wire ropes and structural inspection with eddy current techniques

Systems for the dimensional control of drawn, extruded or welded tubes directly on the production line

Robotized control islands for the automatic control of diameters and ovality on pistons and cylinder liners

Assembly benches with integrated measurement and selection station