Category: Products and solutions

-

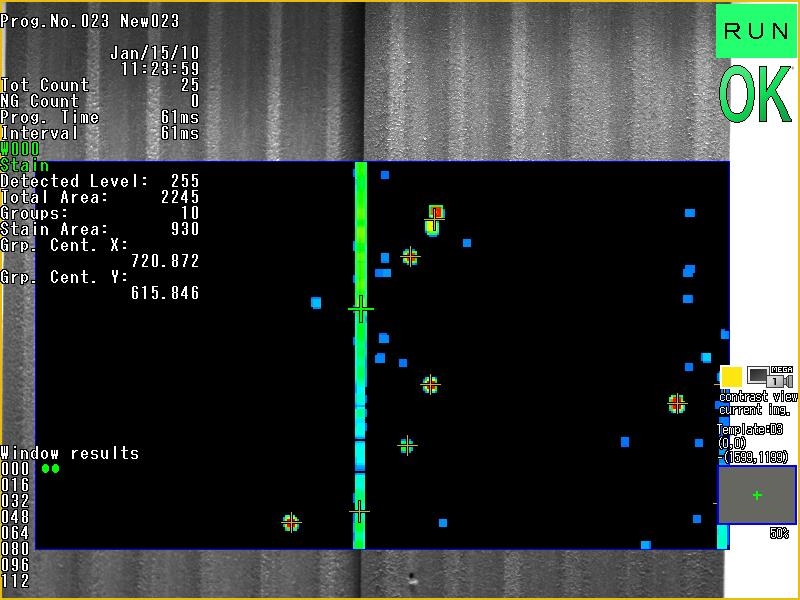

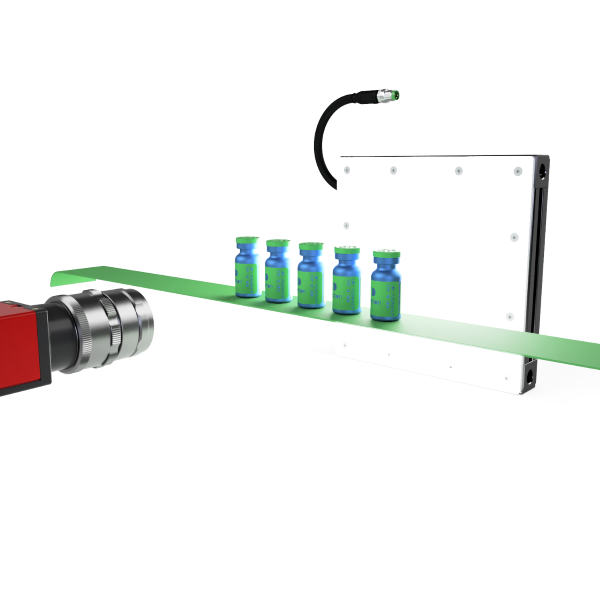

Artificial vision systems for quality control on the production line

Artificial vision systems for the visual and dimensional control of industrial products. The PCL2315 control station is equipped with a latest generation industrial controller capable of processing the images acquired in real time, generating the control response in a few milliseconds.

-

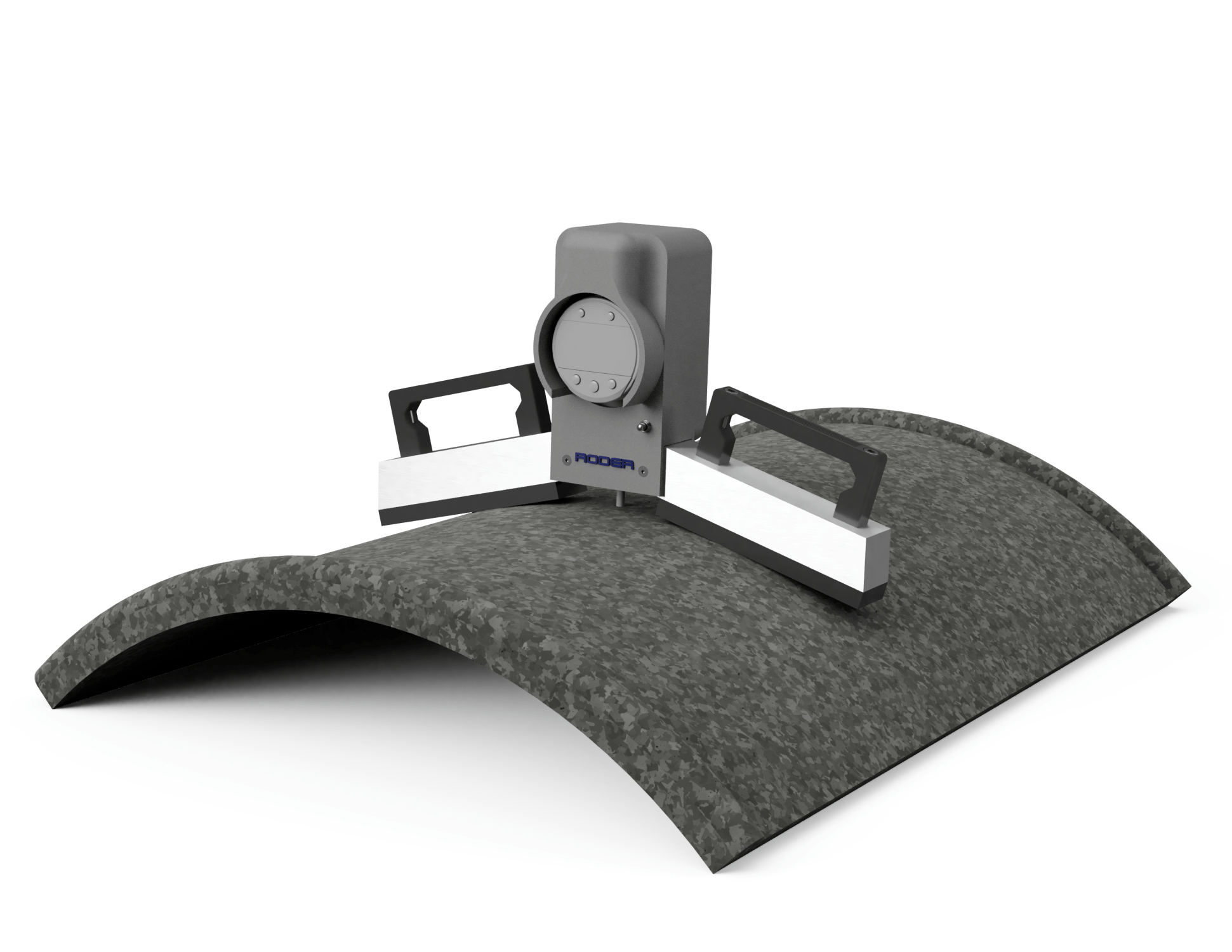

Non-contact thickness measurements on the production line with LASER thickness gauges

LASER thickness gauges for non-contact control of the thickness and width of flat materials. Suitable for measuring the thickness of sheets, strips, boards, profiles and carpets. Non-contact measurement allows you to measure moving objects, even at high speed, or easily deformable materials that with contact measurement techniques…

-

Ultrasonic thickness gauges for corrosion monitoring and quality control

Ultrasonic thickness gauges are a valuable tool for corrosion monitoring and quality control. These are devices that use ultrasound to measure the thickness of materials such as metals, alloys, plastics and ceramic compounds. They are used in a variety of industrial fields ranging from corrosion analysis, to thickness measurement, to maintenance…