Moisture measurement of recycled paper bales

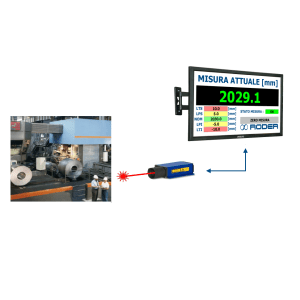

Measurement of the position of beams and pipes in line of position

Use of LASER distance meters for position and distance measurements

DM2 series LED illuminators for ROBOT guide

LED backlighting for vision systems

Digital radius and diameter gauge DIACHECK-CT series

Measurement of the torque and tearing of the cap of bottles, bottles, jars both in screwing and unscrewing

Systems for the control of screwing and unscrewing torque on bottle, bottle and jar caps

Systems for checking defects on continuous products, wires, pipes and cables

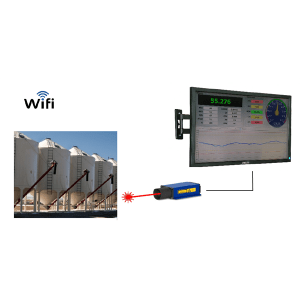

Level measurement in tanks, silos or large containers with level display on remote monitors

Stroboscopes for speed measurement and preventive maintenance

SB-1000 series LASER micrometers for non-contact diameter and width measurement

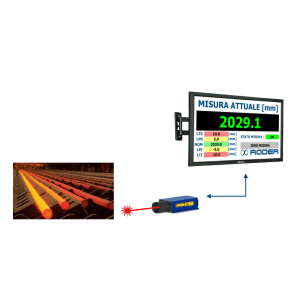

Level monitoring with LASER distance meters and visualization on giant displays

Systems for checking the thickness of slabs and panels in the production line

Determination of the color of on objects, continuous ribbons or reference marks

Monitoring of temperature, humidity, level and volume of biomass

Special components for industrial automation, measurement automation and non-destructive control

AN0045 - Ultraviolet light vision systems for glue and sealant analysis with induced fluorescence technique

Protective cases for sensors and optical instruments

Vision systems for the control of caps, capsules and safety closures in the production line