Category: Automation sector applications

-

RFID traceability of waste paper bales

RODER launches an innovative project based on RFID technology for digital tracking in the paper recycling supply chain, covering the section currently uncovered and guaranteeing complete traceability, from recovery to the paper mill, promoting sustainability and new certification opportunities.

-

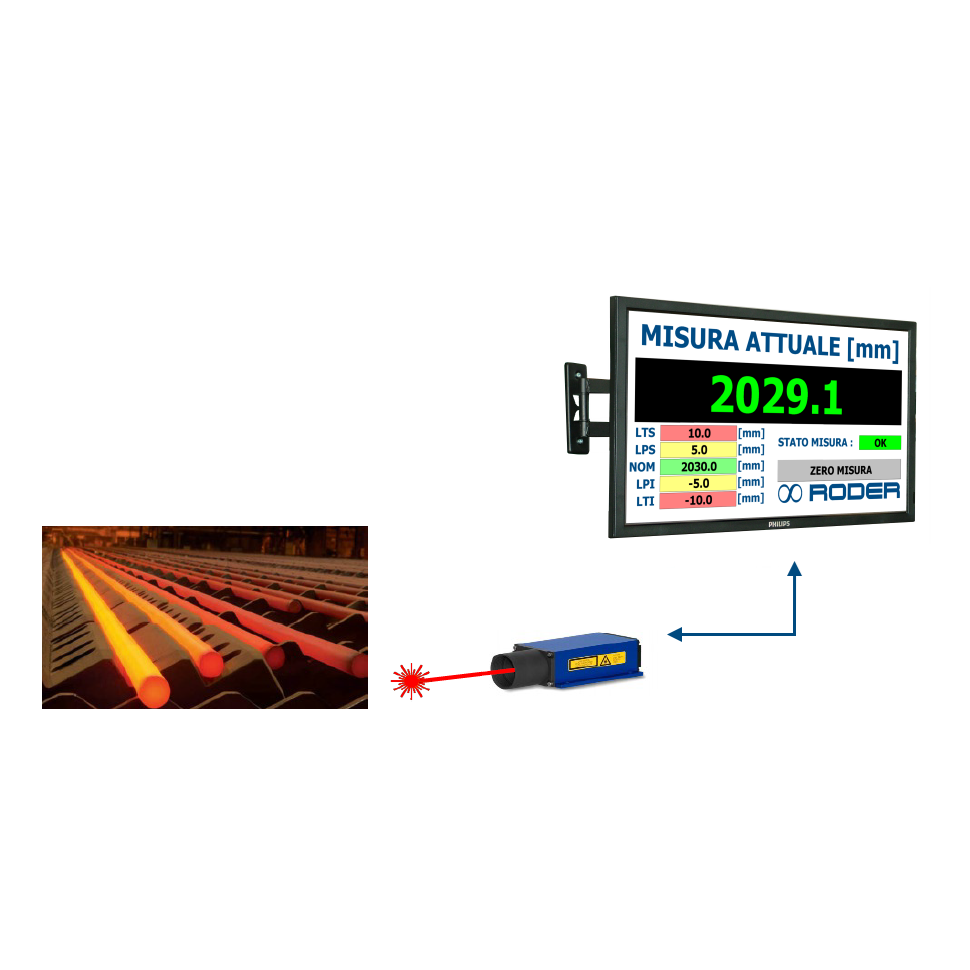

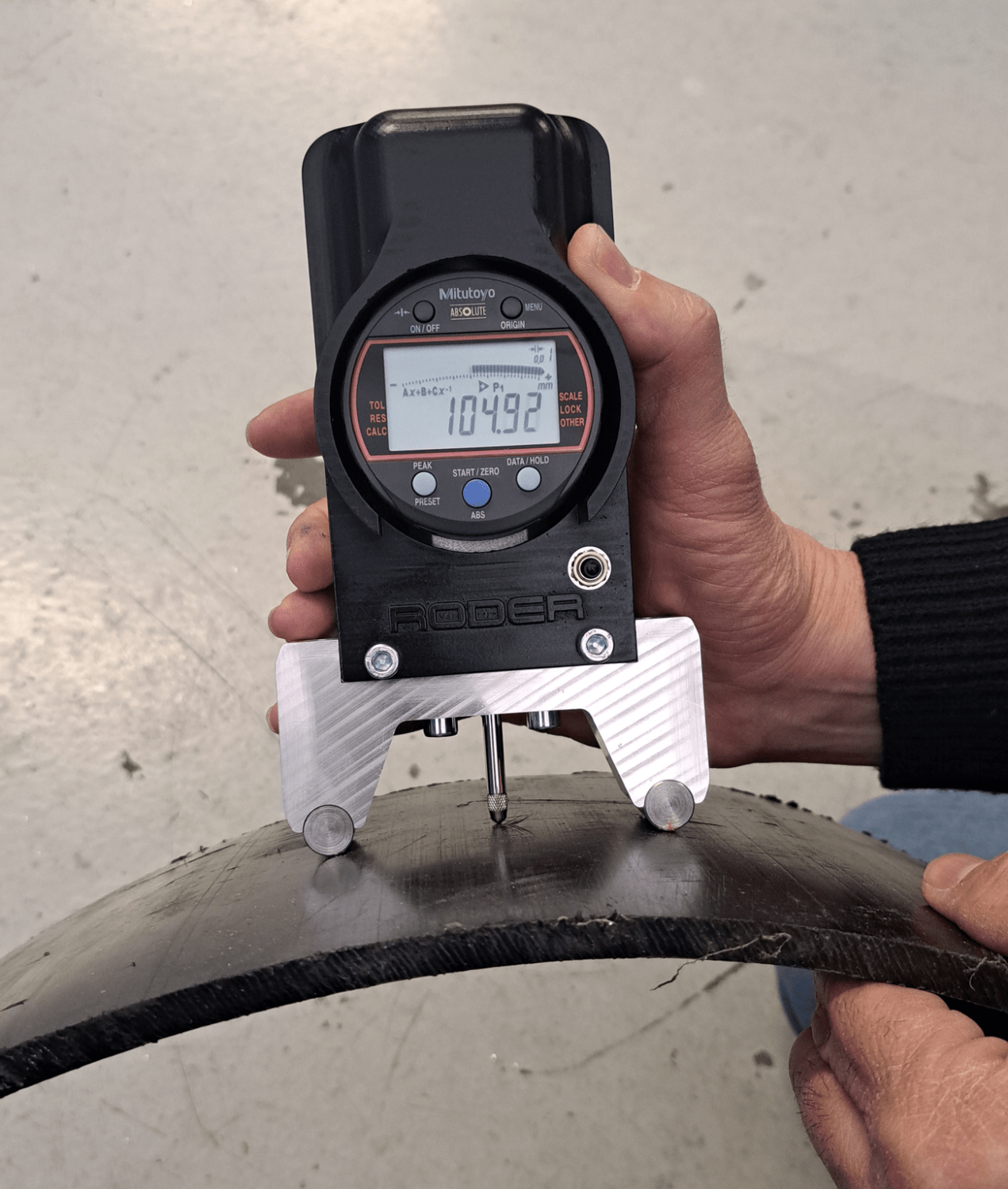

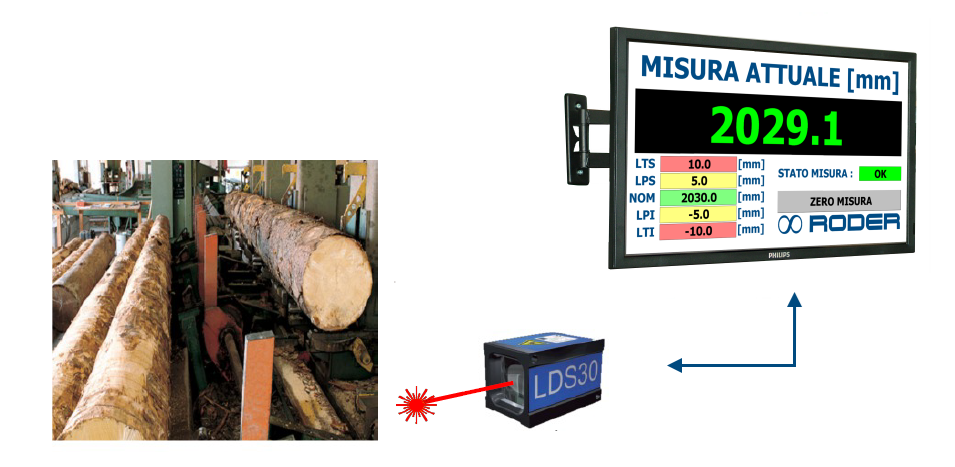

Measurement of the position of logs and wooden panels

LASER distance meters allow easy and quick measurement of the position and length of wooden trunks and panels. The use of LASER distance meters allows the measurement of distances and positions without contact and with high precision. The measurement can be viewed on the display or transmitted remotely.