LASER technology establishes itself as a fundamental ally in professional measurement processes, thanks to its precision and ease of use. Today, engineers and specialized technicians can enjoy the potential offered by laser distance meters, cutting-edge tools for accurately detecting distances. RODER has produced a specific application kit that can elevate the experience of using these devices, optimizing their application in professional contexts.

I LASER distance meters they are devices used to measure a distance precisely, through the use of a laser beam. The excellence in terms of precision and the ability to take measurements in large and hostile spaces makes them indispensable in many sectors, from construction to manufacturing.

La LASER technology, thanks to its accuracy and reliability, represents a crucial solution in modern professional applications. Relatively simple to use, it significantly reduces the margins of error and the time spent in conventional measurement operations.

From today also available for pre-purchase rental!

Easy to use

This kit has been designed to facilitate the use of laser distance meters, offering a complete support system for using the LDM42 LASER distance meter directly in the field.

In practice, the kit allows you to be immediately operational and to limit the wiring and programming operations of the LASER distance meter to a minimum.

Simply connect it to a power socket and the system is immediately operational!

One of the main advantages of this laser distance meter application kit is the ability to integrate it with a remote monitoring system. This allows measurement data to be displayed on giant displays and remote PLCs, greatly simplifying the work of operators and reducing the risk of errors during measurement operations.

Furthermore, RODER's laser distance meter application kit also offers the possibility of storing measurement data and generating detailed reports (combined with an external system), improving work efficiency and ensuring greater precision in quality control operations .

In summary, the RODER laser distance meter application kit represents a complete and high-performance solution to simplify and speed up measurement operations in the metal and semi-finished products sector. Thanks to its reliability and precision, this system is able to guarantee high quality results and optimize the work processes of professionals in the sector.

Features

- Complete ready-to-use kit, complete with connection cables, power cables and sensor programmed for the most popular applications.

- Electronic controller with LCD display and touch screen.

- User-friendly control software, easily configurable and designed to be used even by untrained or qualified personnel.

- The kit can be used to test the LASER distance meter or for a few days, even in non-fixed poses.

- The Kit can be easily converted into a fixed final application by integrating it into the existing production structure.

- The ease of connection and programming allows you to be up and running in just a few minutes.

Optional kit with external monitor

The REDAM-LDM system is supplied in the form of a complete kit and ready for use even by unqualified personnel.

The kit includes:

- 32 inch monitor

- Embedded controller installed on the back of the monitor

- Bracket for wall mounting with VESA connection or alternatively pedestal for table installation

- Power cable for monitor and electronic controller (the sensor is powered directly by the controller through a connection cable

- Connection cable for LDM41 (single data and power cable) 20 meters long.

- Upon request, the LASER sensor already programmed and configured for use can be supplied

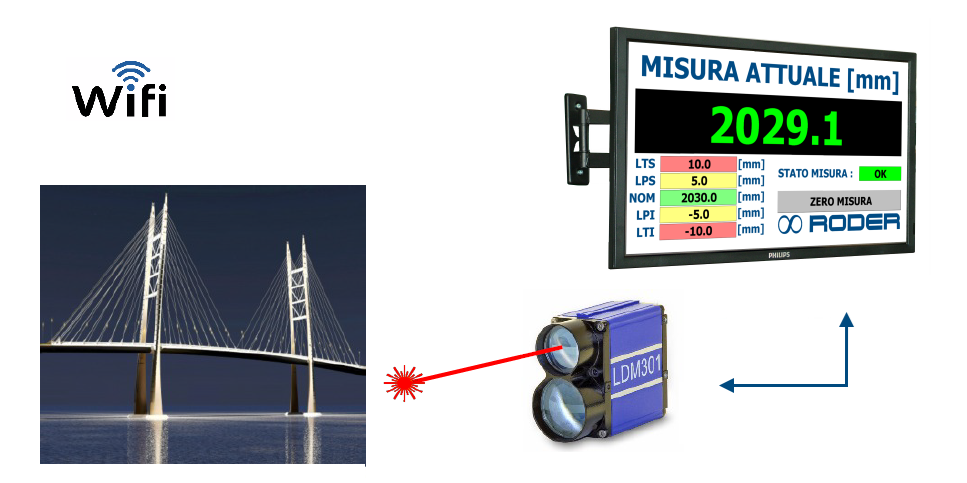

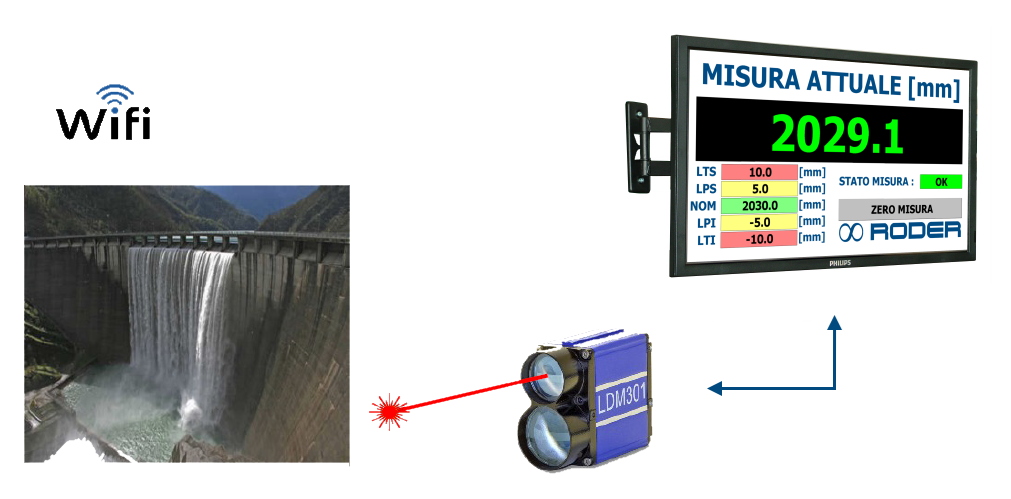

Option for wireless installation

For applications where a wireless connection is required, it is possible to provide an additional kit that manages the Wi-Fi connection between the laser sensor and the display monitor

Applications

Level measurement in tanks, silos or large containers with level display on remote monitors. The LASER sensor allows a precise and fast measurement even of liquid products where the surface reflection index is such as to allow the detection of the LASER spot. The LASER distance meter is a valid replacement for the contact distance meter or the ultrasonic wave detector.

Measurement of size, distance or position of large objects in the metallurgical and iron and steel industry. Real-time communication of position and distance to PLC, HMI or process control devices. With the LASER distance meters it is possible to check the coil diameter during winding for programming the acceleration or deceleration ramps. It is possible to detect the edge position for tracking the movement or the size, thickness, width and length of billets and slabs.

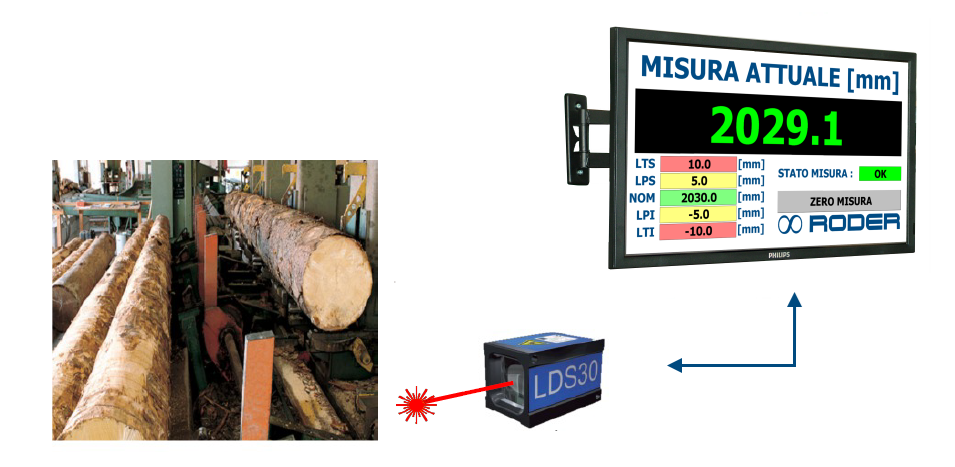

Measurement of length, diameter, ovality and position in the wood sector. With the LASER distance meters it is possible to measure the position of logs or blocks of material before processing. The position, thickness, length or diameter data can be transmitted in real time to PLC, HMI or SCADA systems. The irregularity of the wood surface is not a problem as the LDM series LASER distance meters constantly correct the operating parameters in order to guarantee a precise and reliable measurement.

Dimensional inspection in the paper and textile industry. Control of loop and position of the belt or carpet even in the presence of materials with a change of color or surface appearance. The distance measurement can be transmitted in real time to the line controller (PLC or SCADA) or displayed on a display or on a giant monitor.

Measurement and dimensional control in the metal industry. The characteristics of the LDM series LASER distance meters allow a precise and reliable measurement even in the presence of high temperatures, in the presence of fumes and vapors or on hot surfaces. The problems of heat or light emission by the target to be detected can be eliminated or greatly mitigated with the use of protective cases or with the installation of optical filters

Dimensional control in the metallurgical sector on both hot and cold applications. The LASER distance meter can provide in real time the position, distance and size (thickness, width, length) of slabs, blooms and billets both at room temperature and at high temperatures. The problems of heat or light emission by the target to be detected can be eliminated or greatly mitigated with the use of protective cases or with the installation of optical filters

Position measurement on overhead traveling cranes with anti-collision function. The LASER distance meters of the LDM family allow the real-time detection of the position and distance on bridge cranes and cranes ensuring the anti-collision function. The installation of the LASER distance meters also allows the parallelism to be detected or the two lateral carriers not to synchronize. The display of the position, distance or positioning differential can also be viewed on giant monitors or it is possible to generate alarms or remote signals on the control systems.

Supervision of the railway infrastructure. Detection of the position and speed of trains and moving parts. The ability to detect distances even up to 3 km allows the detection of objects that move over large distances or that must be intercepted at great distances. The ability to work on even very different surfaces or with very high variations in color and reflectivity allows the detection of distance, position and speed even on very different objects.

Measurement and control of the position, deformation and vibrations of large structures or located at very large distances.

The ability to work on even very different surfaces or with very high variations in color and reflectivity allows the detection of distance, position and oscillation even on very different objects. The use of intelligent data loggers allows constant and continuous monitoring even over observation periods of weeks or months. Remote data transmission also allows the monitoring of multiple measurement points or multiple structures from a single observation and control point.

Measurement and control of the position, deformation and vibrations of large structures or located at very large distances.

The ability to work on even very different surfaces or with very high variations in color and reflectivity allows the detection of distance, position and oscillation even on very different objects. The use of intelligent data loggers allows constant and continuous monitoring even over observation periods of weeks or months. Remote data transmission also allows the monitoring of multiple measurement points or multiple structures from a single observation and control point.

- Process monitoring in steelworks and rolling mills

- Distance measurement on hot incandescent steel up to 1300 ° C

- Level measurement in silos and heaps

- Monitoring and positioning of cranes and transport systems

- Position monitoring of vehicles and boats

- Lifting system monitoring / lifting height measurement and lift positioning

- General distance measurement and position monitoring

- Measurement of the diameter of the rolls / reels

- Distance measurement in mining, construction, forestry and material handling technologies

- Detection of thickness, length and width of metal products

- Measurement of the diameter of the steel coils

- Detection of fast moving objects

- Use as a proximity switch

- 2D and 3D scanning applications

- Precision altimeters for cranes and gantries

- Deformation and oscillation measurement of large structures such as dams, bridges, skyscrapers

- Monitoring of mountain slopes or critical points.

- Measurements of slabs, blooms, billets or semi-finished products in the metallurgical industry

- Measurement of cutting position for saws and shearing machines

- Material feed control on presses for molding

- Winding or unwinding material measurement on reel

- Loop control in cutting lines and slitter

- Speed measurement on moving targets

- Level measurement of paints and chemicals

- Measure and control position of ships in port or on approach

Technical characteristics of REDAM-LDM systems

REDAM-LDM series systems are suitable for the realization of measurement and control applications in industrial, geological, railway and port areas

- Wide sensing distances

- Distance measurements up to 300 m without reflector

- Measurements of distances up to 3000 m with a suitable reflective system or with particularly reflective targets

- High detection accuracy

- Optoelectronic measurement methods with latest generation optical and electronic components

- Accuracy up to ± 1 mm

- Constant precision independent of target distance

- Easy integration into automation systems or data acquisition systems

- Flexible parameterization of all working parameters and interfacing with the outside world

- Easy adaptation to the application and type of system

- Various interfaces suitable for industry

- 4 mA .... 20 mA, Profibus, Industrial Ethernet, RS422, RS485, RS232

- Reliable and robust construction

- Aluminum enclosures with degree of protection IP 65 or IP 67

- Integrated heating for outdoor applications

- Use in bright outdoor environments with a high percentage of constant or diffused light

- Safe and harmless

- Visible and infrared laser radiation

- Laser class 1 or 2

- No special precautions for use or additional certifications are necessary

Integration with Wi-Fi wireless networks

RODER SRL can provide all the necessary support for the integration of LASER distance meters in the industrial sector or in the structural control sector. All LASER distance meters can be interfaced through a physical connection (with copper or fiber optic cable) or through a wireless connection (Wi-Fi or proprietary radio link).

RODER SRL can supply standard or customized software for the continuous monitoring of the physical quantities detected by the LASER distance meters. The use of intelligent data loggers allows the control of the physical quantities monitored even for long periods of time and the real-time communication of any anomalies, even remotely via web-servers or remote control systems.

RODER SRL can provide not only the data acquisition and archiving software but also all the hardware necessary for the realization of the final application. Single or multi-channel data acquisition units, point-to-point acquisition systems or distributed control systems are available. It is also possible to centralize data from multiple distance meters on a single control and data storage location.

Learn more about LASER distance meters

The LASER LDM family of distance meters consists of a series of optoelectronic distance measuring devices for industrial applications with analogue interface (from 4 mA to 20 mA) or digital (Ethernet, Profinet, Profibus, RS232, RS422).

The LDM series LASER distance meters are used for the precise measurement of distances from a few meters to three kilometers. The distance measurement represents aconsolidated application for laser technology.

These optical sensors use LASER (pulse or modulated) light to measure distances, heights, lengths, levels and positions in a non-contact process. To achieve this, all components work together in a perfectly coordinated overall system.

This system consists of a laser emitter, optical transmitters and receivers, photosensitive diodes and sophisticated electronics and algorithms for time measurement or phase measurement. We use different optoelectronic principles for our measuring devices, such as time of flight, phase comparison and back-mixing LASER pulse. These methods allow singles accurate measurements to the millimeter, and measuring ranges up to several hundred meters. Using our LASER distance meters is possible measure on natural surfaces or on special reflectors obtaining fast and precise results.

LASER distance meters work using visible or invisible optical radiation and are classified in accordance with current regulations in class 1 or 2 (safe classes for operation even without protective glasses).

The compact construction allows easy installation of the LASER distance meter even where space is limited or in industrial applications. All devices offer standard interfaces, analog or digital data output and parameterizable switching outputs. The family of LASER LDM distance meters is particularly used for applications in the industrial sector with analog (4 - 20 mA) or digital (Ethernet, Profinet, Profibus, RS232, RS422, SSI).

Multisensor monitoring applications

With the REDAM-LDM family of remote displays it is also possible to monitor processes with multipoint sensors and with a multi sensory acquisition network.