Tag: contactless measurement

-

Measurement of the position of beams and pipes in line of position

Laser technology is essential for industrial measurement due to its precision and ease of use. RODER laser distance meters offer a complete and high-performance solution, optimizing the application in professional contexts. The kit allows immediate operation, integration with remote monitoring and generation of detailed reports, improving work efficiency and precision.

-

Application Kit for the use of LDM42 industrial LASER distance meters

The AK1 Kit represents an effective and practical solution for the use of industrial LASER distance meters. The product, based on the LASER LDM42 distance meter, is ready to use and does not require any programming or wiring by qualified personnel.

-

Use of LASER distance meters for position and distance measurements

LASER technology establishes itself as a fundamental ally in professional measurement processes, thanks to its precision and ease of use. Today, engineers and specialized technicians can enjoy the potential offered by laser distance meters, cutting-edge tools for accurately detecting distances. RODER has produced a specific application kit that can elevate the experience of using…

-

Flatness measurement with multi-dimension control units and LVDT linear transducers

MODULCHECK series dimensional and geometric control systems for the measurement and determination of conformity of mechanical parts and discrete objects using objective measurement procedures that are easily managed even by non-expert personnel.

-

Dimensional checks with multi-quota control units and LVDT linear transducers

MODULCHECK series dimensional and geometric control systems for the measurement and determination of conformity of mechanical parts and discrete objects using objective measurement procedures that are easily managed even by non-expert personnel.

-

SB-1000 series LASER micrometers for non-contact diameter and width measurement

Laser micrometers for diameter and width measurement on the production line. The measurement of diameter and width with laser micrometers allows the control of the dimensions of continuous products directly on the production line, without contact and in maximum safety for the operator. SB-1000 series LASER micrometers A wide range of application modes…

-

Level monitoring with LASER distance meters and visualization on giant displays

Level measurement in tanks and silos with continuous monitoring of the level trend Generation of low level or overflow alarms Automatic calculation of volume or weight with continuous monitoring on multiple tanks RODER presents the new series of giant REDAM LDM displays to create systems visualization and monitoring to be connected to…

-

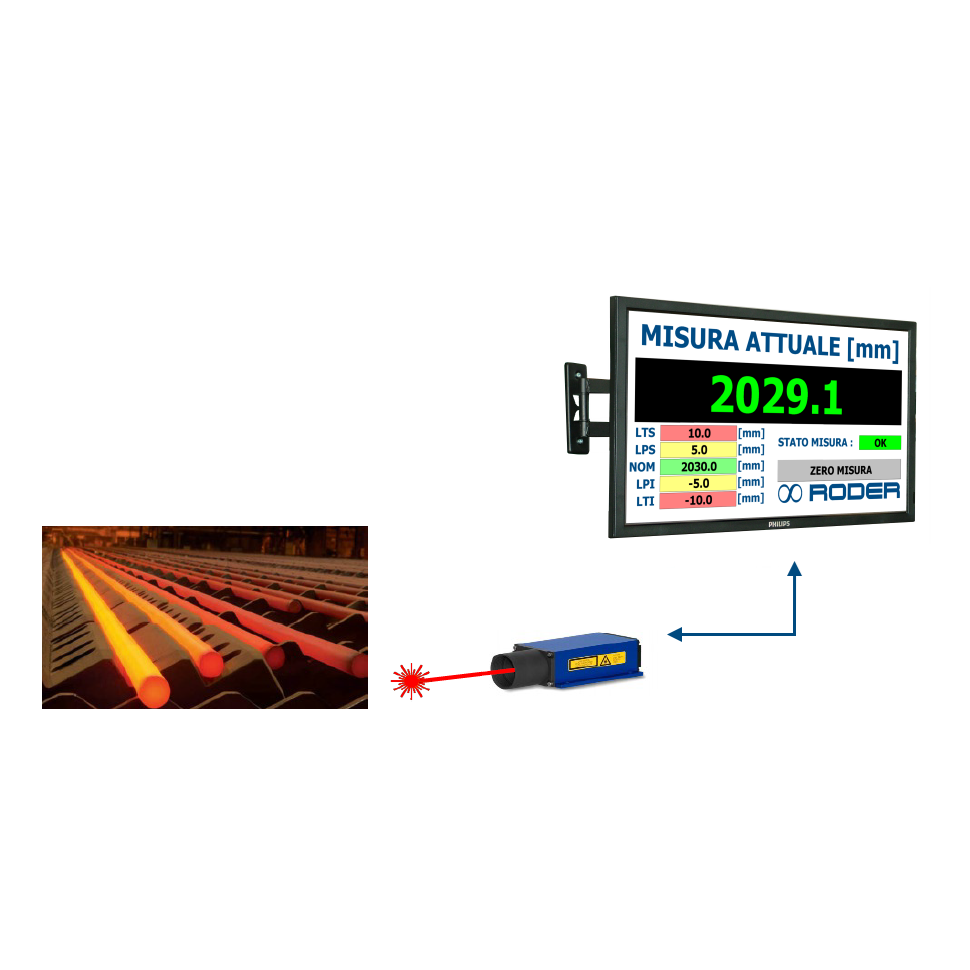

Monitoring of distances, positions, lengths and depths with LASER distance meters and visualization on giant displays for the metallurgical and steel industry

Applications for measuring distance, positions, lengths and depths with industrial laser distance meters for the steel and metallurgical sector. Generation of out-of-tolerance alarms with visual signaling (light turret) or with electrical contact for sirens and alarms. Direct connection to PLC, SCADA systems or remote data acquisition systems. Viewing the…

-

Distance and position measurements with industrial laser distance meters

LASER distance meters for industrial applications Non-contact distance measurement in total safety Visible LASER with safety class 2 also suitable for measurements in the presence of an operator Analogue data output, RS232, RS422, Profinet, Profibus, Ethernet. The family of LASER LDM distance meters is composed of a series of optoelectronic distance measuring devices for…