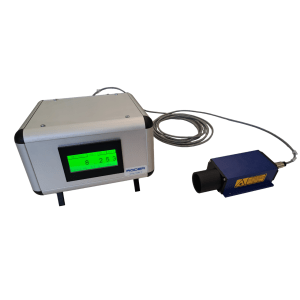

Thanks to the AK1 Kit it is possible to evaluate the performance of the LDM42 industrial LASER distance meters in a very short time and without the help of an installer or software engineer. Simply connect the power socket, position the distance meter in front of the target to be measured and the sensor will immediately show the value on the display.

The AK1 Kit was designed to simplify the use of the LDM42 industrial LASER distance meters, making it accessible to everyone, even to unqualified personnel.

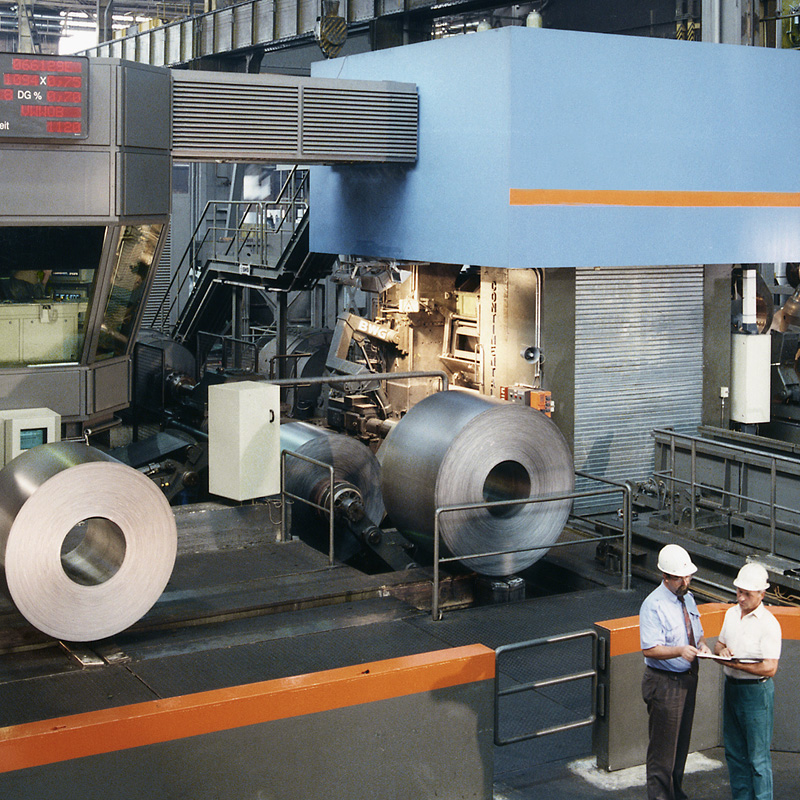

In production environments, Accuracy in the placement of materials and structures is crucial. Often, the use of LASER distance meters is the ideal solution, but the installation and configuration process can prove to be a problem, requiring specialist skills.

To address this problem, RODER's AK1 KIT offers a simple and efficient way to use a LASER distance meter like the LDM42 model, without having to resort to programmers or electricians.

Upon first startup, the system immediately initializes the LASER distance meter with a series of standard parameters. The user can then choose whether to keep the pre-set parameters or customize them according to needs. At subsequent startups the system uses what has been set by the user.

Benefits found

- Installation speed : just power it up and the system is immediately operational

- Ease of use : no programming is needed, the distance value is immediately displayed

- Parameterizable: If the application requires customization, all additional parameters can be set via the touch screen

- Possibility of remote connection : if necessary the kit can be connected to PLC, SCADA or remote monitors through special communication interfaces

Products used in this application

LDM42 series LASER distance meters

- LASER distance meters for distance measurements up to 30 meters on natural surfaces or 100 meters with reflector

- Power supply 24 Vdc

- RS232 - RS422 interfaces - Profinet, Profibus and Ethernet / IP

- Visible LASER emitter (red) with safety class 2

- Accuracy up to +/- 1 mm

- Wide range of accessories for high temperature environments or for environments with high contaminants

Deepening

The AK1 KIT not only simplifies the use of LDM42 LASER distance meters, but also opens up new possibilities regarding the automation and control of production processes. The intuitive user interface allows you to quickly define custom parameters to adapt to different operating contexts, without having to go through complex programming procedures.

With the AK1 KIT, specialized technicians and installers can save valuable time, allowing them to focus on more strategic, high-value tasks. Furthermore, the simplified use of LASER distance meters reduces the dependence on highly specialized figures, making the management of human resources within companies more flexible.

A “ready to go” KIT

RODER's AK1 KIT is not only a practical solution for using LASER distance meters, but is a step towards accessible industrial automation. Industry 4.0 requires greater integration of advanced technologies within production processes, and solutions like this allow small and medium-sized businesses to be brought closer to a level of automation previously reserved for larger companies.

The flexibility and ease of use offered by the AK1 KIT are an example of how technology can be adapted to meet the most specific needs of the industry. RODER's innovation opens up new perspectives for the efficiency and competitiveness of businesses, offering a positive counterweight to costs in terms of human and material resources.

Widely used for testing features

RODER has already successfully implemented the AK1 KIT in a variety of industrial sectors, demonstrating the ease of integration and positive impact on processes. The company has shared insights and case studies on its website, providing potential customers with a clear view of the positive effects KIT can have on their businesses.

One of RODER's customers, for example, reduced first-time installation and configuration time from days to just a few hours, substantially improving uptime and reducing downtime. Another case study highlighted how the AK1 KIT simplified the updating and maintenance of LASER distance meters, allowing timely intervention and optimal resource management.

The array of case studies serves to show that RODER's innovation is not just theoretical, but has a concrete impact on the operational results of industrial companies.

RODER's AK1 KIT offers an effective way to simplify and speed up the use of LASER distance meters in industrial contexts. Its user-friendly interface and ease of setup and installation allow technicians and installers to exploit the full potential of these tools without the need for specialized skills.

The adoption of solutions such as the AK1 KIT represents an important step towards the modernization and optimization of production processes. By reducing implementation costs and simplifying the use of complex technologies, industrial companies can improve their competitiveness and prepare for the challenges of an increasingly global and dynamic market.

In conclusion, the ease of use and operational benefits offered by solutions such as the AK1 KIT demonstrate that innovation does not necessarily have to involve complexity. Conversely, when it is well designed, it can be an enabler for businesses, allowing them to effectively adapt to the needs of an ever-changing manufacturing landscape.

Tools division partner : www.innovacheck.com