Category: Carpentry and heavy construction applications

-

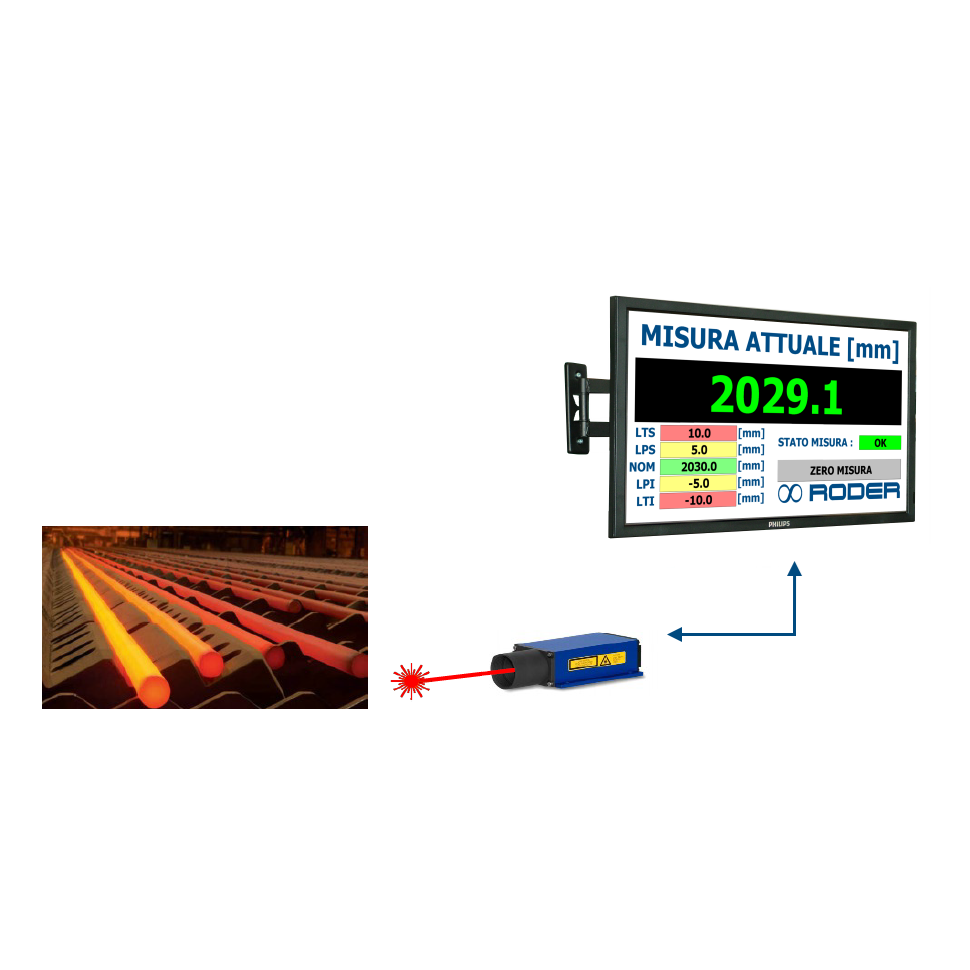

Systems for measuring the position, displacement and deformation of large structures

Systems for measuring the position, displacement and deformation of large structures can be extremely complex. Laser dimensional inspection technology offers a simple and effective way to address these issues. Laser distance meters are devices that use a light beam to measure the distance between two points with precision and accuracy…

-

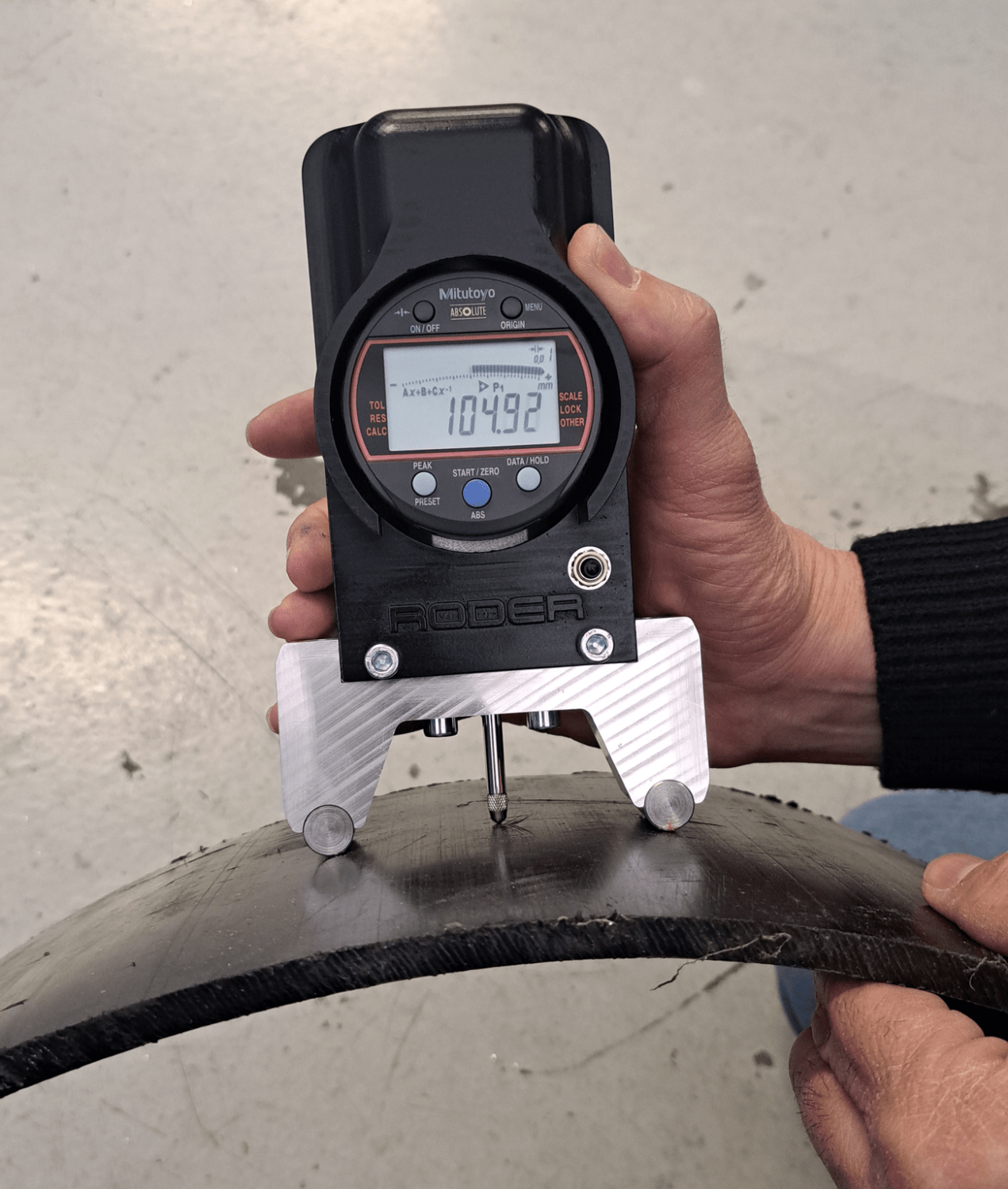

LASER scanner for dimensional and geometric control of continuous products in the production line

Laser scanning systems are a type of inspection technology used in the manufacturing industry to provide an accurate measurement of the shape and dimensions of products. Laser technology offers unrivaled precision in the inspection and measurement of complex contoured products, including 3D profiles. Furthermore, the speed and reliability with which a laser can perform…

-

Electronic control units and electrical panels for data acquisition and process control in the production line and metrological laboratory

Profile detection of pressed, blanked, drawn or welded sheet metal parts with extraction of geometric or dimensional information Measurement of angles, distances, openings, positions to verify the correct execution of the processes or as preparation for welding and assembly operations Comparison with the model mathematician for determining control quotas Applications on…