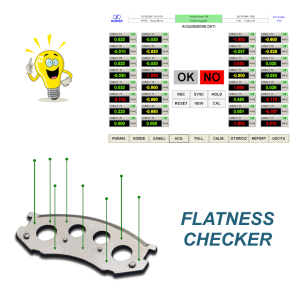

Flatness measurement on blanked parts

RFID traceability of waste paper bales

Control of defects on continuous products

Measurement of the position of beams and pipes in line of position

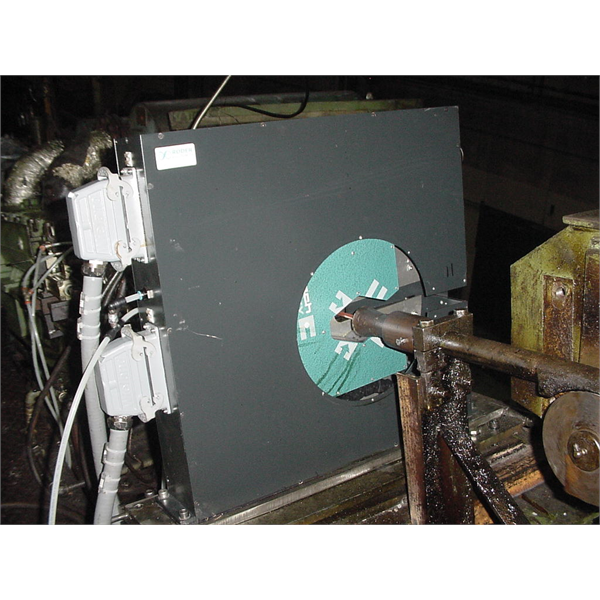

Bending measurement on tube and profile benders

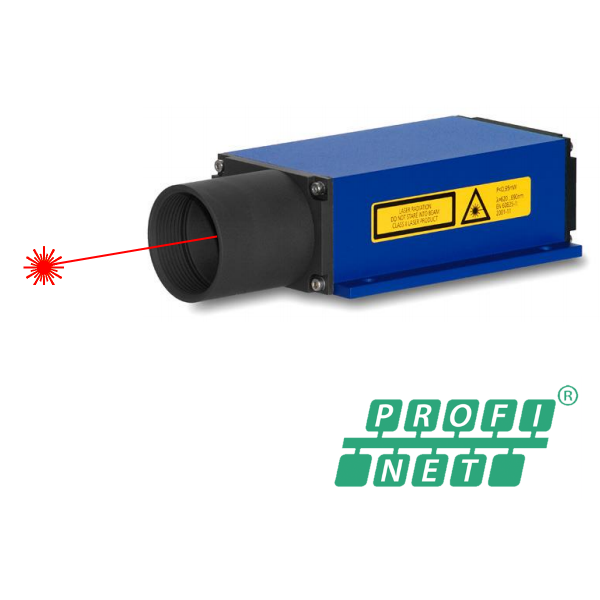

Application Kit for the use of LDM42 industrial LASER distance meters

Use of LASER distance meters for position and distance measurements

Measurement of the radius of curvature with digital archimeters

Flatness measurement with multi-dimension control units and LVDT linear transducers

Dimensional checks with multi-quota control units and LVDT linear transducers

Systems for checking defects on continuous products, wires, pipes and cables

Stroboscopes for speed measurement and preventive maintenance

DIACHECK measuring instruments for internal diameter measurements

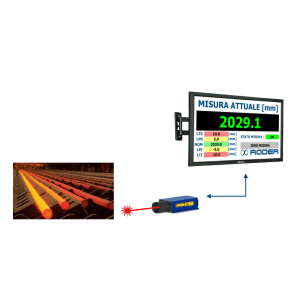

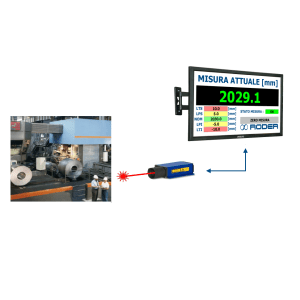

Monitoring of distances, positions, lengths and depths with LASER distance meters and visualization on giant displays for the metallurgical and steel industry

Level monitoring with LASER distance meters and visualization on giant displays

Measurement systems and optical profilometers for the measurement of railway profiles

Systems for dimensional and geometric control of railway halls

Robotic islands for quality control with artificial vision systems

Automatic equipment for dimensional and geometric control with LVDT contact probes

Dimensional control of drawn bars in the production line

Measurement of the thickness and width of metal strips in the production line

Systems for traction control on mechanical components and assembled systems

Special components for industrial automation, measurement automation and non-destructive control

Artificial vision systems for integrity control, OCR recognition and dimensional control in the production line

Artificial vision systems for visual inspection of wire ropes and structural inspection with eddy current techniques

Measuring systems for checking the alignment and parallelism of press surfaces and processing machines

Manual measuring systems for quality control and statistical calculation in the production line and metrological laboratory

Protective cases for sensors and optical instruments