Category: Chemical sector applications

-

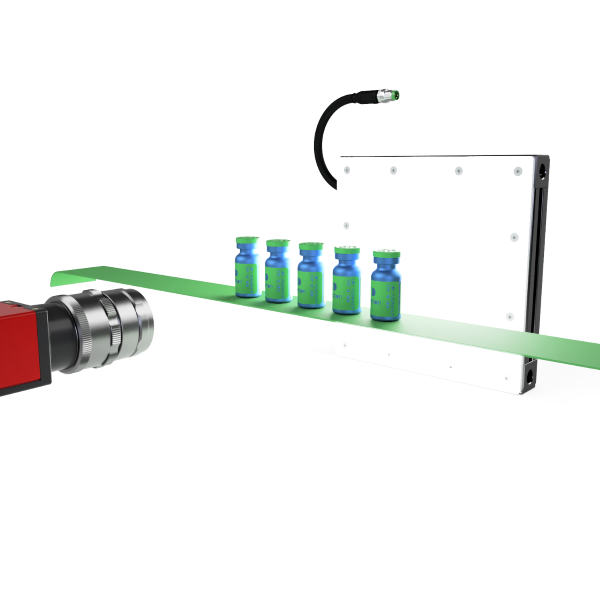

Measurement of the torque and tearing of the cap of bottles, bottles, jars both in screwing and unscrewing

Cap torque meters for measuring the tightening torque, both during screwing and unscrewing, of bottle caps, barrels, containers, jars, bottles, containers and cans. Cap torque meters for measuring the tightening torque, both during screwing and unscrewing, of bottle caps, barrels, containers, jars, bottles,…

-

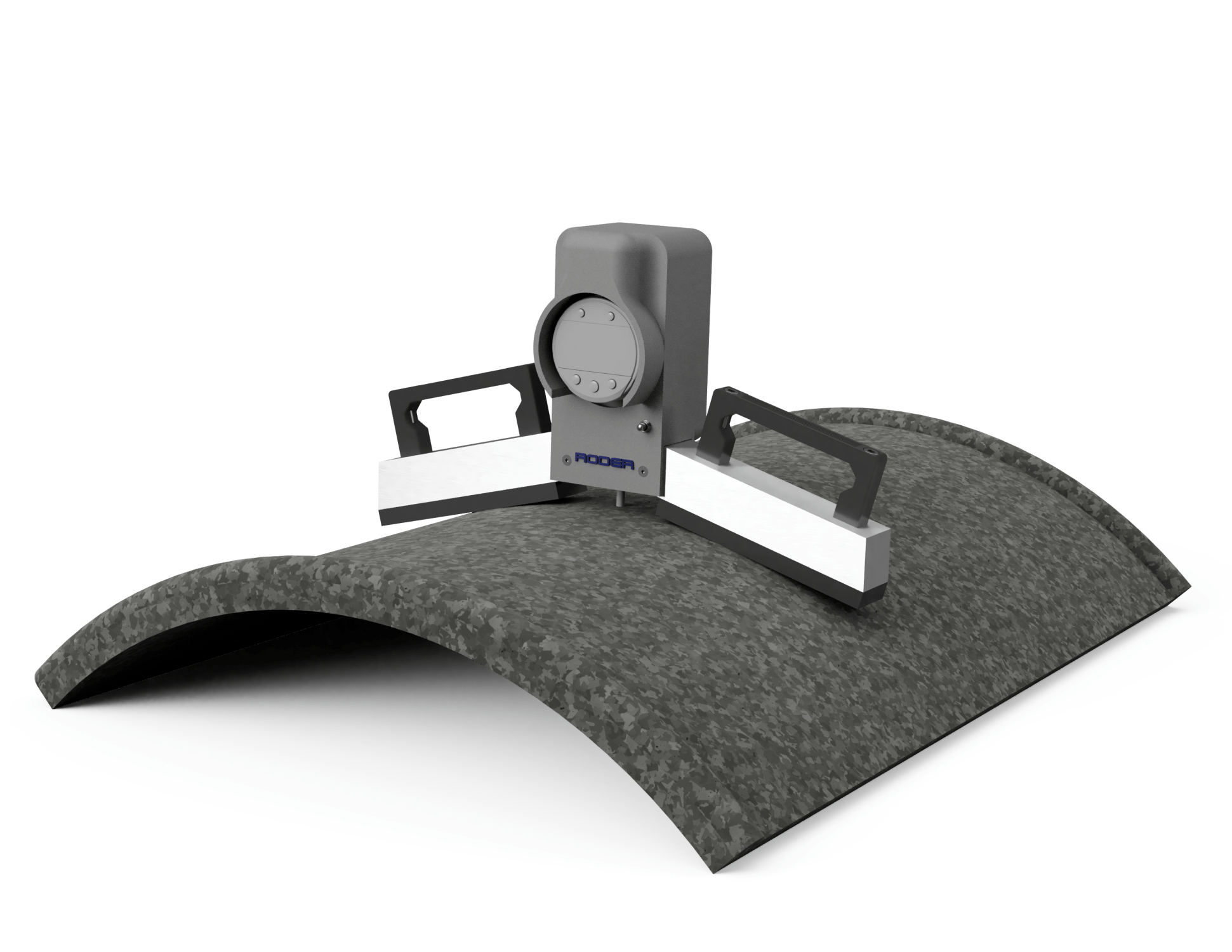

Dipping machines

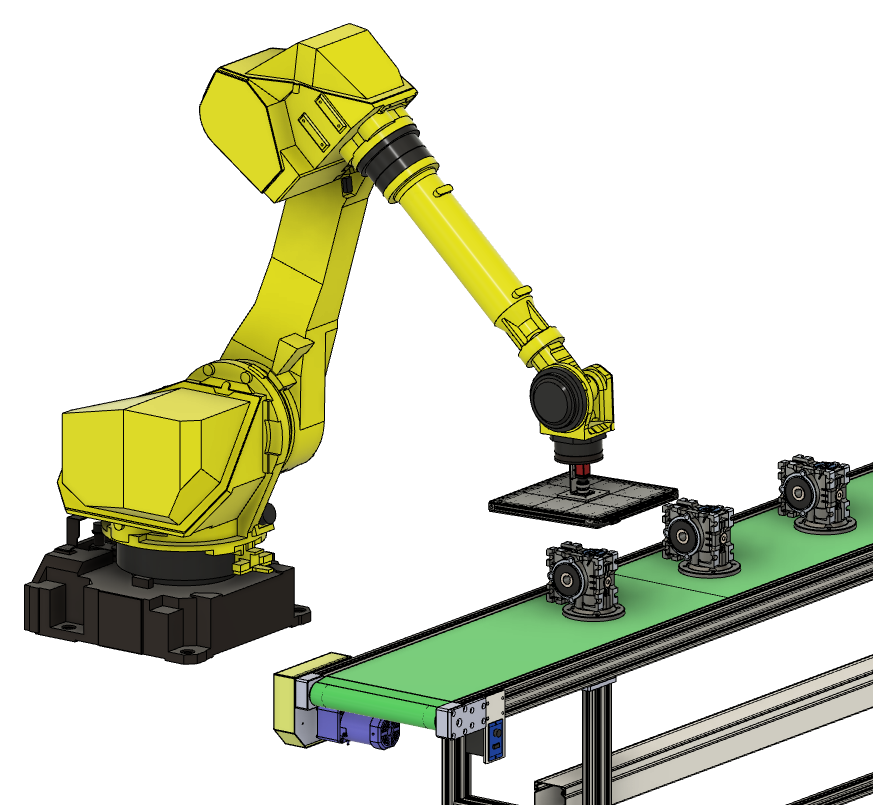

Profile detection of rubber and latex details with extraction of geometric or dimensional information Measurement of angles, distances, openings, positions to verify the correct execution of the processes or as preparation for welding and assembly operations Comparison with the mathematical model for the determination of control quotas Applications on robotic islands,…

-

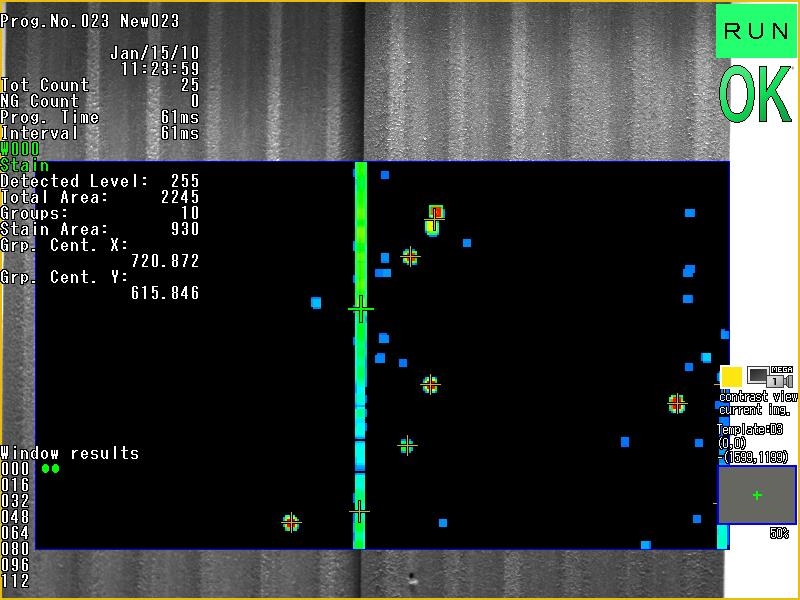

Determination of the color of on objects, continuous ribbons or reference marks

Color detection with extraction of geometric or dimensional information Color measurement to verify the correct execution of the processes or as preparation for welding and assembly operations Comparison with the mathematical model for the determination of control dimensions Applications on robotized islands, on Cartesian axes or in automatic assembly islands…