Welcome to RODER

Measuring systems, measuring instruments

and quality control technologies,

process control and industry 4.0

Featured products

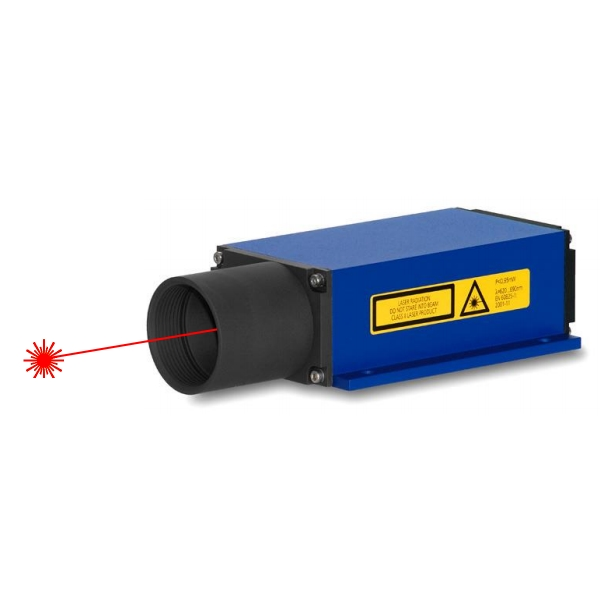

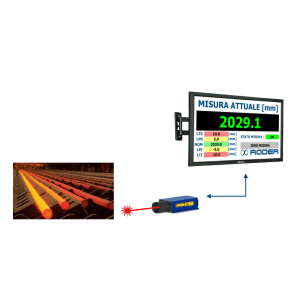

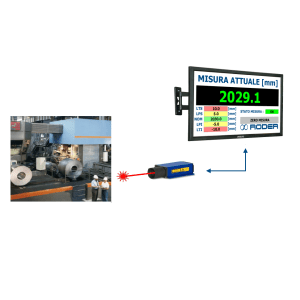

LASER distance meters LDM42

LASER distance meters for distance, length, volume, displacement and vibration measurement applications.

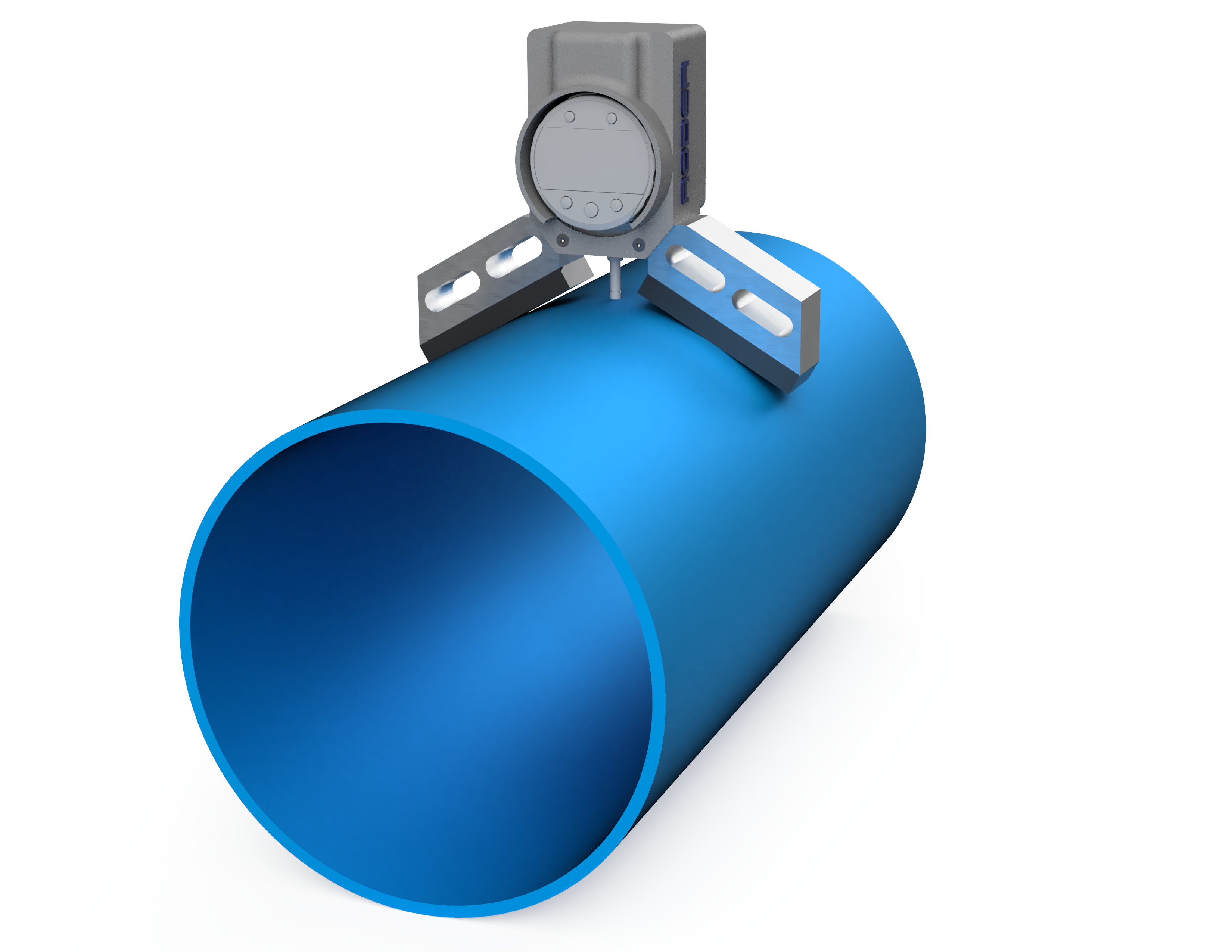

DIACHECK-CT archometers

Digital archimeters for measuring curvature radii and diameters of profiles, tubes, calenders, cylinders, bars, glass, sheets.

Latest news from RODER

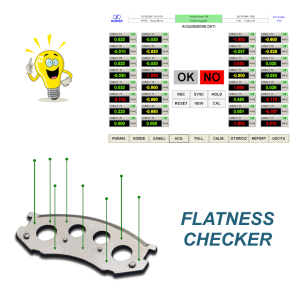

Flatness measurement on blanked parts

RFID traceability of waste paper bales

Control of defects on continuous products

Moisture measurement of recycled paper bales

Measurement of the position of beams and pipes in line of position

Bending measurement on tube and profile benders

Application Kit for the use of LDM42 industrial LASER distance meters

Use of LASER distance meters for position and distance measurements

Dimensional checks with LASER sensors

DM2 series LED illuminators for ROBOT guide

Radius measurement on curved furniture products

LED backlighting for vision systems

Digital radius and diameter gauge DIACHECK-CT series

Measurement of the position of logs and wooden panels

Measurement of the radius of curvature with digital archimeters

Dimensional controls of metallic materials at high temperatures

Measurement of the torque and tearing of the cap of bottles, bottles, jars both in screwing and unscrewing

Flatness measurement with multi-dimension control units and LVDT linear transducers

DL1 series LED illuminators for vision systems and optical inspection benches

Dimensional checks with multi-quota control units and LVDT linear transducers

Consulting

The RODER SRL team of technicians is not limited to the presentation of a simple commercial proposal but extends to consultancy and support for the creation of "turnkey" applications or for the definition of data acquisition architectures.

The applications addressed can be in the industrial field, in the research and development sector or in the metrological laboratory.

Innovation in process measurement and control

RODER SRL offers sensors, transducers, measuring instruments and measurement systems for industrial applications, process control, metrology laboratories or for research and development. The proposed technologies can be integrated into the production system and connected with IT systems for management compatible with Industry 4.0 technologies.

RODER SRL is the ideal partner for the study and implementation of measurement and data acquisition systems in the production sector or in research and development laboratories.

Support

Do you have a specific problem to solve?

Do you want a suggestion on the technology to use?

Have you purchased a product and would like help installing or configuring it?

Our team of technicians can help you and advise you on the best solution.

Why rely on RODER SRL?

Thirty years of experience in the design, construction and installation of measurement and data acquisition systems

Team made up exclusively of technicians and engineers working in the metrological and process control sector

INNOVATION

The technologies proposed by RODER SRL are the most innovative on the market and selected from the major global manufacturers of measurement instruments and technologies.

CONSULTANCY

RODER SRL offers instruments, measurements and sensors with technical and application consultancy from the first contact with the customer.

SUPPORT

The mission of RODER SRL does not end with the commercial proposal but also continues the after-sales support, integration assistance and operational maintenance of the proposed products.

“…. Valuable pre-sales consultancy which led to the correct choice of the product and saving precious time in solving the problem....”

JOHN ROMAN

“…. The support team technicians were quick and efficient in resolving the initial setup issue of the test tool. A real added value….”

ANDREW EXPOSED

“…. The availability and support of RODER SRL's laboratory technicians was decisive in choosing the correct technology for our application....”

MARINA BECCHIS

Let's work together on your new one

project !

We will be happy to help you realize your new project.