Detection of diameter and ovality with extraction of geometric or dimensional information

Measure of angles, distances, openings, positions to verify the correct execution of the workings or as preparation for welding and assembly operations

Comparison with the mathematical model for the determination of controlling shares

Applications on robotic islands, on Cartesian axes or on automatic assembly islands

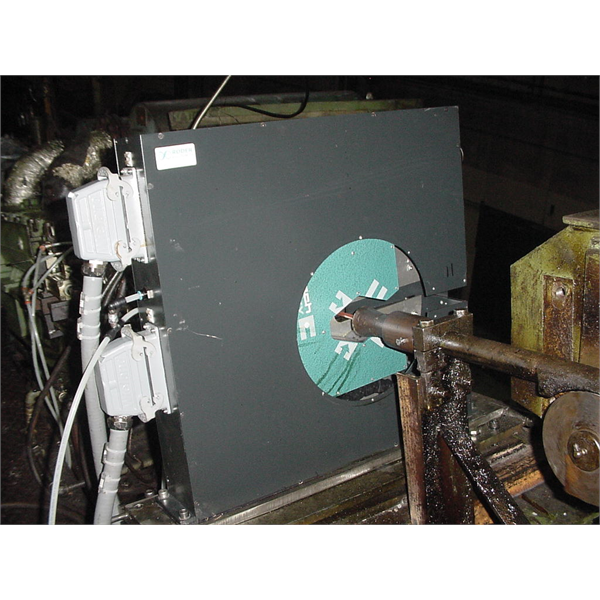

Measure with high precision, non-contact LASER technology, even on high speed materials, easily

deformable or at high temperature. Systems with fixed or tilting LASER sources able to perform

analysis also on square, rectangular or hexagonal sections. Versions for high temperatures or environments with

presence of environmental contaminants. Interfacing with line PLC and management software. LASER systems with accuracies up to

+/- 1 micron and up to 2000 scans per second. Real-time visualization of the material profile. Control software with technology

SCADA or traditional. Intuitive and immediate display of anomaly and out of tolerance conditions.

Remote data transmission and interfacing with management systems.

Copyright by RODER SRL - All rights reserved - Application note AN0058