Camshaft profile detection with extraction of geometric or dimensional information

Measure of angles, distances, openings, positions to verify the correct execution of the workings or as preparation for welding and assembly operations

Comparison with the mathematical model for the determination of controlling shares

Applications on robotic islands, on Cartesian axes or on automatic assembly islands

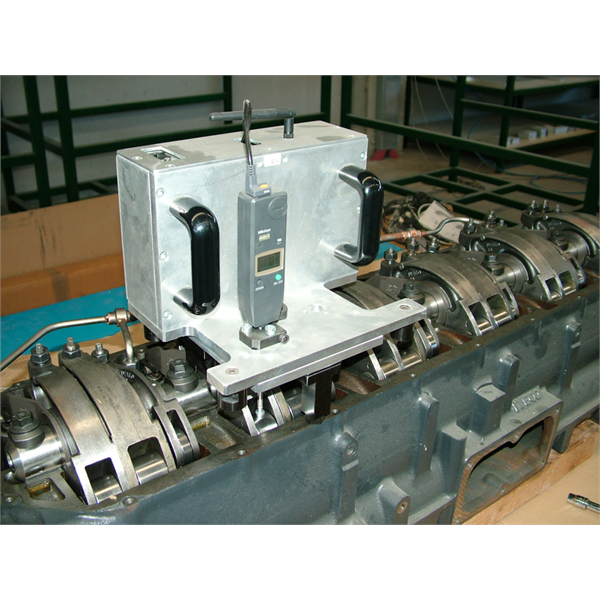

Control island that allows the adjustment of the TDC (top dead center) of a

internal combustion engine. The system provides for the controlled movement of the crankshaft

until it reaches a precise position (TDC) and allows the correct

assembly of the components that will determine the correct timing of the work cycle of the

engine. The system loads the correct timing value from the management system

according to the engine model being assembled. The operator

is guided in all the operations of assembling the measuring equipment on the base and

in all sequential assembly and verification operations. The values detected and the correct

sequence of operations are recorded in a specific report and transferred to the database

of the production line for later consultation and to ensure correct

product traceability.

Copyright by RODER SRL - All rights reserved - Application note AN0033