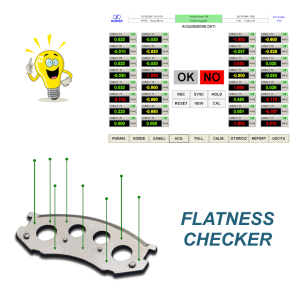

Flatness measurement on blanked parts

Control of defects on continuous products

DM2 series LED illuminators for ROBOT guide

LED backlighting for vision systems

Digital radius and diameter gauge DIACHECK-CT series

Measurement of the radius of curvature with digital archimeters

Flatness measurement with multi-dimension control units and LVDT linear transducers

Dimensional checks with multi-quota control units and LVDT linear transducers

Artificial vision systems for the control of defects on continuous products in the production line

LASER scanner for dimensional and geometric control of continuous products in the production line

LVDT linear transducers for dimensional and geometric control

SB-1000 series LASER micrometers for non-contact diameter and width measurement

LASER scanner for checking the profile of paper, cardboard and embossed products

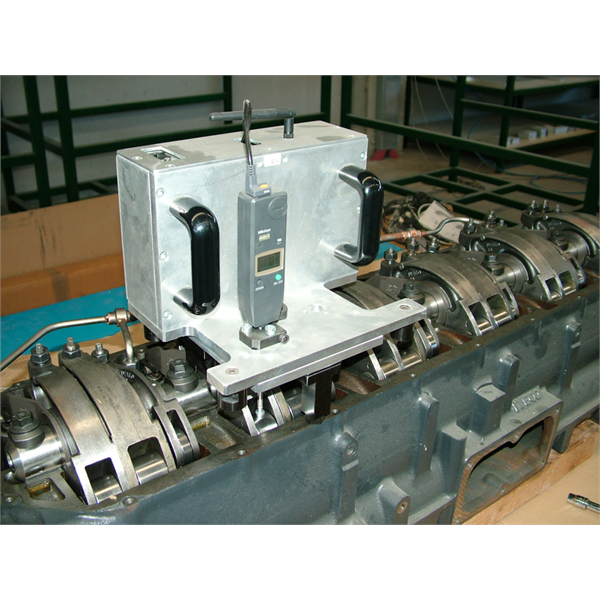

Systems for the control of the axial play of crankshafts and pulleys in internal combustion engines

Systems for the control of timing on camshafts

Systems for the control of timing and height of the top dead center in the production line

RIMAS - Robotic system for inspection, measurement and assembly of mechanical parts

Robotic control islands for automatic hardness control on pins and mechanical parts

Robotic islands for quality control with artificial vision systems

Automatic equipment for dimensional and geometric control with LVDT contact probes

Measurement of diameter and ovality of pipes, wires and cables in the production line

Multidiameter LASER scanner for multi-wire control on drawing, galvanizing and enamelling lines

Measurement of the width of continuous tapes in the production line

LASER scanner for thickness measurements on easily deformable materials

Systems for checking the thickness of slabs and panels in the production line

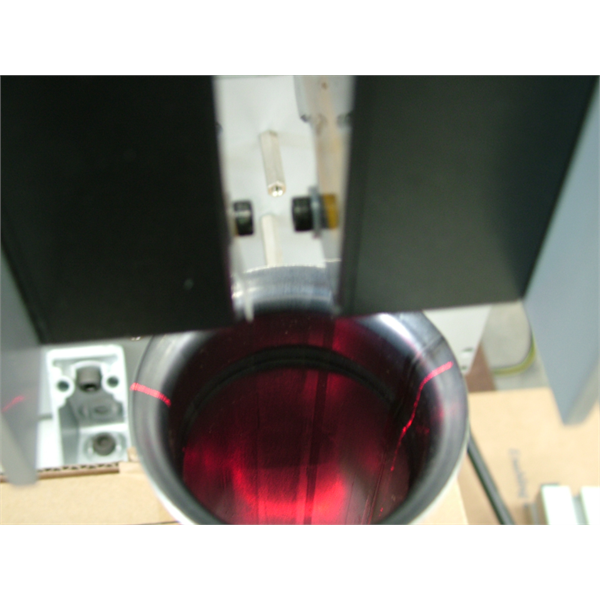

Measurement of the deep drawing and flaring profile of pipes and flanges

Control of the welding profile on automatic machines with LASER scanner

Measurement of oscillation and vibration of shafts, belts and pulleys with laser comparators and optical triangulation sensors

Distance, position, displacement and level measurement with laser distance meters