Measurement of the position of beams and pipes in line of position

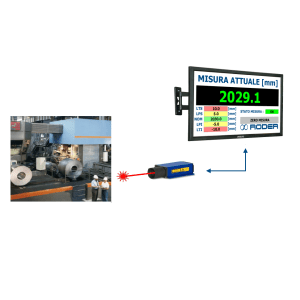

Bending measurement on tube and profile benders

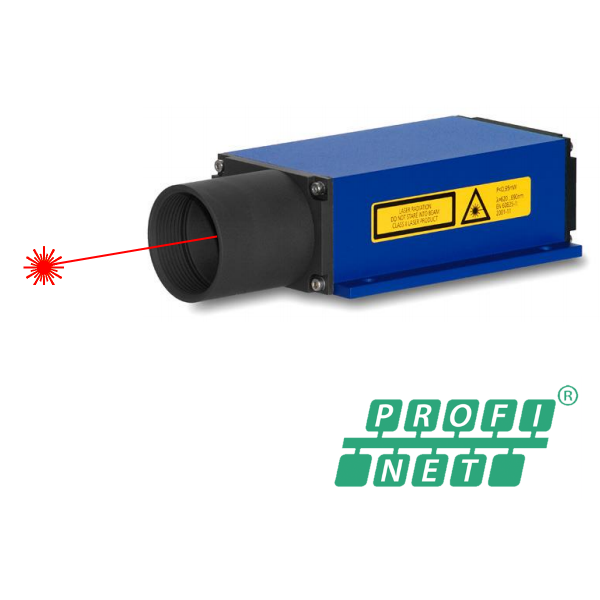

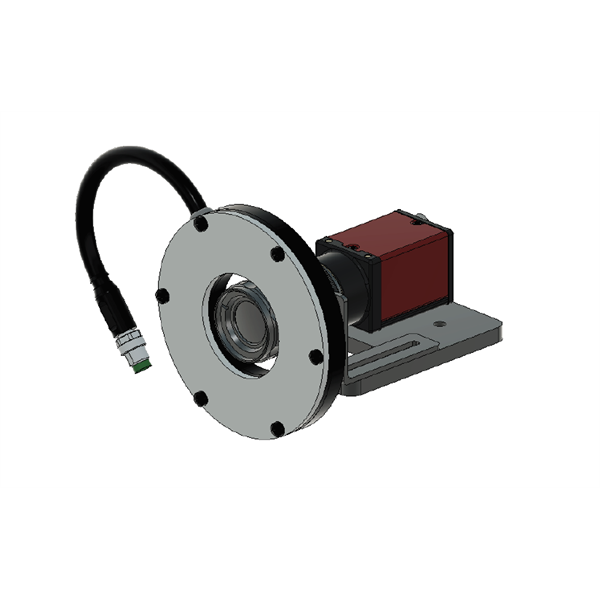

Application Kit for the use of LDM42 industrial LASER distance meters

Use of LASER distance meters for position and distance measurements

Measurement of the radius of curvature with digital archimeters

Systems for measuring the position, displacement and deformation of large structures

LASER scanner for dimensional and geometric control of continuous products in the production line

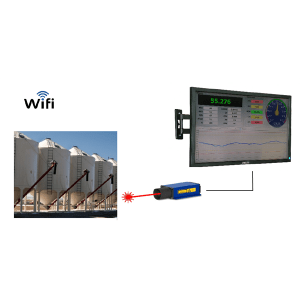

Level measurement in tanks, silos or large containers with level display on remote monitors

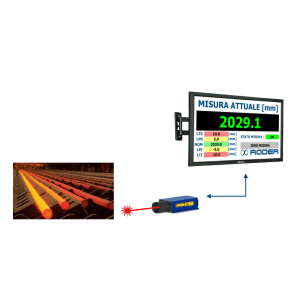

Monitoring of distances, positions, lengths and depths with LASER distance meters and visualization on giant displays for the metallurgical and steel industry

Level monitoring with LASER distance meters and visualization on giant displays

Systems for checking the thickness of slabs and panels in the production line

Control of the welding profile on automatic machines with LASER scanner

Special lighting systems for production line vision systems

Electronic control units and electrical panels for data acquisition and process control in the production line and metrological laboratory

Equipment for checking the tensioning of ropes and cables

Ultrasonic measuring instruments for thickness measurements

Laboratory systems and software for data acquisition from comparators, micrometers and digital gauges

Systems for the dimensional control of drawn, extruded or welded tubes directly on the production line

Profile measurement of pressed, sheared, drawn or welded sheet metal parts