Tag: automation systems

-

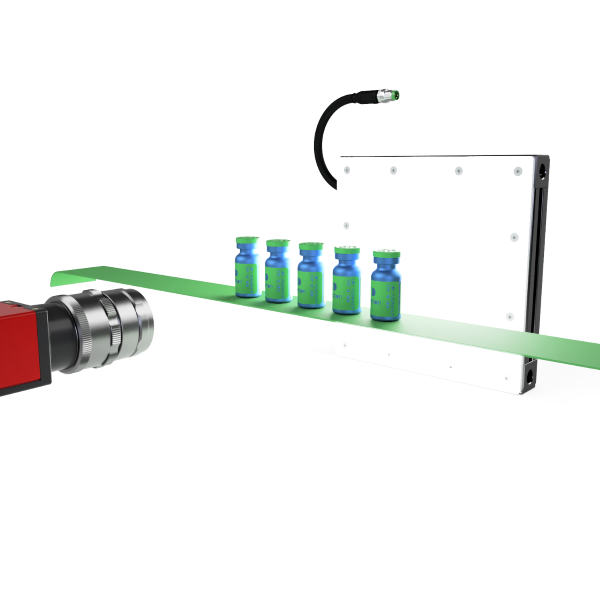

LED backlighting for vision systems

LED backlight systems for industrial automation and machine vision applications. Suitable for vision systems based on the principle of shadow projection. Large illumination area and high uniformity.

-

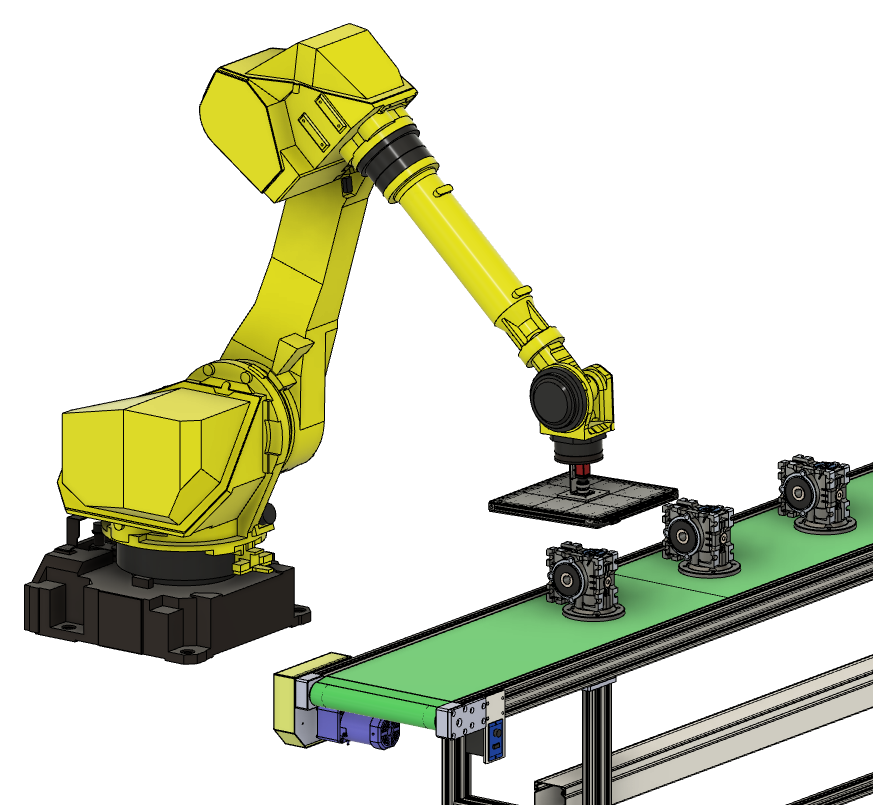

DM2 series LED illuminators for ROBOT guide

LED lighting systems with camera fixing bracket for ROBOT guide and industrial automation.