Stroboscopes for fixed and portable industrial applications

Stroboscopes are tools that allow you to observe and study a moving object, which can be rotary or oscillatory, as if it were stationary, as well as measure its speed.

The operating principle is based on the observation, in low light conditions, of the object in repetitive and constant movement, illuminated by very short flashes of high intensity light.

When you observe a perfectly still image of the object in motion, it means that the flashing frequency of the stroboscope coincides with the speed of rotation or of the oscillatory motion. You can then read on the instrument the speed measurement itself, without any contact with the moving material

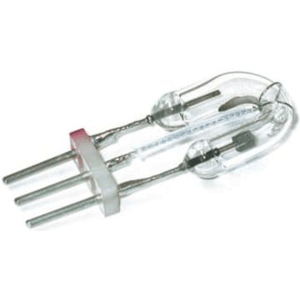

The main element consists of a special Xenon or LED lamp capable of emitting up to 5000 flashes per second, or 300000 per minute. This very high frequency value allows you to observe an object that cyclically moves, vibrates or rotates on its axis even at very high frequencies.

ST-4000 series portable LED stroboscopes

- The large array of 21 LEDs creates a large and bright viewing area

- Quick and easy adjustment of the flash with the x 2 / ÷ 2 buttons and fine adjustment +/- allow precise setting of the flash

- The backlit LCD display facilitates viewing in poorly lit areas

- The large trigger-activated handle reduces the fatigue of holding the device in the hand for extended periods of time

- Quick charge internal rechargeable battery

- Possibility of activating the flash by an external sensor connected with the supplied connection cable

ST-5100 series portable LED stroboscopes

- The motion detection laser translates the detected speed directly into the flash frequency of the light output, simplifying operation.

- The large array of 21 LEDs creates a large and bright viewing area

- Quick and easy adjustment of the flash with the x 2 / ÷ 2 buttons and fine adjustment +/- allow precise setting of the flash

- The backlit LCD display facilitates viewing in poorly lit areas

- The large trigger-activated handle reduces the fatigue of holding the device in the hand for extended periods of time

- Quick charge internal rechargeable battery

- Possibility of activating the flash by an external sensor connected with the supplied connection cable

DT735 series portable stroboscopes

- The bright LED display makes it easy to see in poorly lit areas

- Lightweight and compact design

- Easy flash dial adjustment combined with x2 / divide 2 and fine tune +/- buttons allows for precise flash setting

- Quick charge internal rechargeable battery

- It includes an upper and a lower handle to allow the user to choose the type of use they prefer

DT-311D series portable stroboscopes

- Heavy-duty construction ensures exceptional durability

- The highly focused reflector eliminates “blind” areas of vision.

- The external trigger input allows the unit to automatically synchronize with the equipment

- Universal 85-240 VAC power capability allows a single model to handle a multitude of local power requirements

- Easy tripod or permanent mounting with integral mounting thread

DT-366 series portable LED stroboscopes

- LED technology significantly extends the life of operation and eliminates the need to replace burnt out bulbs

- The backlit LCD display makes it easy to use even in poorly lit areas

- Easy adjustment with the flash ring combined with the x2 / ÷ 2 and fine adjustment +/- buttons allows for precise flash setting

- The quick-charge rechargeable battery guarantees exceptional long-term reliability of use

- Adjustable flash pulse duration allows for clearer images for detailed inspections

- Phase shift (in degrees of delay) allows visual analysis of rotating or reciprocating objects across all points of motion / time / angle

- The flash rate can be synchronized with the process speed via the sensor or controller input

- 1 / 4-20 UNC connection for permanent mounting applications (remove trigger handle)

DT-326B series portable LED stroboscopes

- Wide flash range 60 - 120.000 flashes / min. (1-2000 Hz) can be adjusted to suit almost all high speed applications

- Adjustable flash pulse duration allows for clearer images for detailed inspections

- Line Power 100 - 240 VAC Operates with AC adapter for continuous use or with rechargeable battery for maximum portability

- Phase Shift Advances or delays flash timing to display gear teeth, cutting surfaces, repeats, or “drifting” images.

- The input sensor trigger function allows process machinery to control the flash rate

- Delay time adjustment combined with leading or trailing edge activation simplifies process setup when using an external signal input

- Buttons x2 and 1/2 for adjusting the adjustment speed or +/- for fine adjustment

- Long life LED operation

ST-320BL series portable LED stroboscopes

- Wide flash range 60 - 120.000 flashes / min. (1-2000 Hz) can be adjusted to suit almost all high speed applications

- Long life LED for UV ink applications

- Adjustable flash pulse duration allows for clearer images for detailed inspections

- Phase Shift Advances or delays flash timing to display gear teeth, cutting surfaces, repeats, or “drifting” images.

- The input sensor trigger function allows process machinery to control the flash rate

- Delay time adjustment combined with leading or trailing edge activation simplifies process setup when using an external signal input

- X2 and 1/2 keys for large adjustment rate variation or +/- for fine adjustment

- 1 / 4-20 UNC connection for permanent mounting applications (remove activation handle)

Typical applications of stroboscopes

- Measurement of print speed and quality in the printing industry

- Rotation speed measurement of pulleys and gears

- Checking the integrity of the transmission belts

- Iinspection of high speed motors and electrospindles for special machining

- Predictive maintenance and preventive on rotating parts: motors, shafts, gears, rototi, blades

- Inspection e quality check on printing and pad printing machines

- Observation of the behavior of pulse jets, water jets, blowing

- Check correct rotation of fans, cams, gear teeth

- Vibration analysis

- Audio speaker analysis

- Timing control e checking the sharpness of cutting blades.

- Check correct operation high speed winders.

Speed and quality measurement in the printing industry.

The use of strobes allows you to carry out slowed observation of the process of production on machines that have repetitive processing cycles. On machines equipped with synchronization photocells, or with the signal coming from the machine PLC, it is possible to perform one fast and immediate synchronization of the strobe with the production process and see the product exactly as if it were stopped directly during printing, die-cutting or during packaging. In addition to the observation of slowed down movement, the stroboscopes allow you to take measurements and count the number of strokes per minute of the machine. This function is particularly useful for determining the productivity of a plant or for calculating the hourly production of a machine.

Preventive maintenance and correct mechanical assembly check

It is not always possible to observe the behavior of moving mechanical parts to verify their correct assembly or the presence of abnormal vibrations due to irregular wear. The use of strobes allows you to freeze the movement of gears, levers, valves or any mechanism that works with repetitive motion at a high number of times per second. The slowing of the movement, carried out through the synchronization of the stroboscope flash, with the movement of the object under observation, allows the slowed observation of the object, identifying any movement defects, shape or size defects that could compromise the reliability of the object. 'application.

Control of printing and correct setting in the textile and paper sector

Strobes allow you to freeze the motion of a continuous object or tape that has repetitive motion or regular printing. In this way it is easy to see if a trademark, logo or text is printed correctly, without smudging, with the correct color and font references.. Typical applications also include observing print quality directly on the production line, immediately after printing, without waiting for the printed reel or ribbon to be stopped and analyzed at a later stage. The possibility of inspecting the print directly on the production line allows you to identify the problem immediately, avoiding the production of material that would otherwise be waste.

Stroboscopes - Introduction to choice

There are many stroboscopes on the market with very different characteristics and prices.

In this section we collect some tips that we believe may be invaluable in selecting the correct tool.

Intensity and quality of light

Much of the cost of the stroboscope is determined by the quality of the lamp used and the amount of light it is capable of emitting.

Stroboscopes must be able to emit flashes of light with an extremely short pulse duration, in the order of a few microseconds (some drop below 10 microseconds), otherwise the strobing effect is not visible or the quality of the display of the object is poor.

Not only must the lamp emit fast and very bright pulses of light but it must also be able to last for several million cycles because the stroboscopic effect is often observed at very high frequencies.

Therefore all the goodness of the stroboscope is played on the quality of the lighting system.

Often medium-low end stroboscopes characterized by very competitive costs employ lamps whose duration is limited in time and the light emitted is of insufficient intensity to observe the object.

Furthermore, some stroboscopes do not allow to change the lamp compromising the use of the entire instrument when the lamp has exhausted its life. Always pay attention to the possibility for a stroboscope to be able to change the lamp (unless it is an LED stroboscope and therefore maintenance-free).

Another problem that must always be kept in mind is the presence of ambient light. In fact, it is not always possible to work in a completely dark environment and the light emitted by the stroboscope must always contrast the light of the surrounding environment.

Very often inexpensive stroboscopes are tested in completely dark environments and when working in the field the desired effect is not obtained.

Xenon and LED technology

There are essentially two technologies on the market: Xenon and LED.

Xenon technology allows to obtain flashes of light with high energy (and therefore high luminous intensity) and with very competitive costs.

But the Xenon lamp is prone to deterioration. It is therefore necessary to provide for replacement after a few million flashes.

LED technology has the advantage of having a practically unlimited life and does not require the replacement of the lamp. It also has the advantage of being able to emit a much higher number of flashes per minute than Xenon technology.

The disadvantage of LED technology is the higher purchase cost (partly amortized by the absence of maintenance) and the lower light produced at the same price range (although in the future with the technological evolution of LED systems there will be a rapid reduction costs).

The emission optics

All the light produced by the lamp must be directed to the object to be illuminated.

The design and construction of the optical part of the stroboscope must be treated in detail.

Stroboscopes of medium-low range and characterized by very low costs often have the optical part with the passage of months loses the characteristics of brightness or light transmission with the consequence of no longer having the characteristics of initial brightness.

Portable instrument batteries

As for all devices powered by rechargeable batteries (mobile phones, cameras, personal computers) the choice of good quality batteries allows to keep the stroboscope in conditions of efficiency and duration.

On the contrary, low quality batteries tend not to guarantee a correct recharge and consequent limited working times or malfunctions in the light emission system.

A battery powered stroboscope should always have a system of high quality batteries and above all interchangeable in order to maintain the quality of the product purchased over time.

The accuracy of the Flash

Very often stroboscopes are used not only to "freeze" the movement of an object but also to measure its frequency of movement or rotation.

The accuracy in generating the pulses also determines the accuracy of the measurement. Cheap strobes also tend to have very low accuracies in determining the frequency of movement.

The accessories

Often the operator using the stroboscope does not work in the laboratory but directly on the production lines or in difficult environments.

The presence of a complete set of accessories guarantees complete freedom of use of the stroboscope (carrying cases, protective cases, belt clip, support tripods, fixing brackets, multi-voltage power supplies).

The availability of a wide range of accessories allows the stroboscope to be used in any operating condition and in any practical application.

The external trigger

The ability to use an external trigger is a useful one function to be able to "lock" the driving frequency of the lamp stroboscopic to the production machine or to a certain event.

In this way the flashing frequency of the stroboscope is “automatically” linked to the production machine and therefore it takes less time to examine the repetitive movement to be examined with the stroboscope.