MODULCHECK series dimensional and geometric control systems allow the measurement and determination of conformity of mechanical parts and discrete objects using objective measurement procedures that can be easily managed even by non-expert personnel. The innovative architecture on which the MODULCHECK system is based allows the creation of dimensional and geometric test benches (static or dynamic) using easily available equipment and sensors and easily editable during setup or directly in production also by the end customer.

MODULCHECK systems are suitable for measurements directly on the production line and also managed by unqualified personnel. The visualization interface has been deliberately made simple and easy to consult but without renouncing the powerful mathematical functions intended for the analysis of dimensional and geometric characteristics.

All production data are stored in a local database with the possibility of transferring or synchronizing with existing databases (SQL, XML or CSV) for a complete and reliable analysis of data in real time.

Measurement of diameters, heights, thicknesses, depths on mechanical parts with traditional bench measuring instruments

The MODULCHECK system allows the measurement of any mechanical detail (bushings, rings, flanges, shafts, gears) with traditional manual measuring instruments (gauges, micrometers, comparators, bore meters). It is possible to quickly and reliably acquire measurements of internal diameter, external diameter, height, thickness, width and depth using easily available instruments, with reduced costs and decimal, centesimal or thousandth precision. The MODULCHECK system guides the operator in carrying out the measurements in a predetermined sequence and at the end of the procedure provides the response of the control. All data are sold stored in a database that allows both a real-time analysis of the production trend (through trends, histograms and production indices) and an analysis of the production history through the division into production lots.

Measurement and control of flatness on molded, cut, forged or rectified parts

The MODULCHECK system allows the measurement in rapid times and directly in the production line of the flatness of molded, sliced, laminated or die-cast parts. The flatness measurement is carried out with a sensor matrix capable of detecting differences compared to a certified calibration master. The test result is a mapping of the verified areas with the relative numerical value of deviation from the ideal shape. A very intuitive graphic presentation allows you to quickly and reliably determine the areas of non-compliance. All the data obtained can be used for statistical calculations (Sigma, Cp, Cpk, Cm, Cmk) or for the realization of control cards (XS, XR, process trend, population distribution).

Flexion, swing and deformation measurement

The MODULCHECK system allows the control of dimensions and positions in space detected by LASER sensors (triangulation laser sensors, laser micrometers or laser distance meters). The dimensions detected by the LASER sensors can be correlated with each other for the determination of deformations, torsions, bending, vibrations. The measurement report can be generated in Excel - CSV format or directly in graphic format. The use of EDAC modules allows to correlate dimensional and geometric information with information derived from temperature, humidity, force, torque sensors. In this way it is possible to correlate the dimensional test with data of thermal excursion, variations in ambient humidity or with forces and torsions involved in the dynamic test.

Radial and axial oscillation measurement (radial and axial runout)

The MODULCHECK system allows measurement with non-contact measuring instruments (LASER triangulation sensors and LASER distance meters) of real-time radial and axial oscillations. The typical application is the determination of the radial and axial rounout of wheels, tires, rims and wheel hubs. The report can be both numerical and graphical. With the addition of optional mathematical analysis libraries, it is possible to analyze the harmonics of the acquired signal to determine the harmonic composition of the swing, from the fundamental up to the 32nd harmonic. The software can be installed both on a fixed workstation (desktop personal computer or industrial panel PC) and on a mobile workstation (notebook or tablet).

Roundness, oscillation, cylindricity, profile measurement

The MODULCHECK system, combined with dimensional dimensional test benches, allows the determination of geometric characteristics of parts subjected to rotation on tailstocks. It is thus possible to measure diameters, ovalizations and oscillations but also roundness, cylindricity and data of the radial profile of the object (important in applications such as the measurement of camshafts). The measurement can also be acquired by measuring machines specially developed for this type of control in the metrological laboratory or in the production line (3D measuring machines, profilometers, optical machines).

Shape check

The MODULCHECK system allows to carry out the shape control of objects of any size and material. The shape check is carried out by comparison with a reference master and all the differences are highlighted quickly and intuitively. It is possible to generate signals of out of tolerance or of partial non-conformity of the product. The system can also be installed in robotic control areas and unattended automatic control benches. In this configuration, all verification operations can be controlled directly by a PLC or an automatic production system.

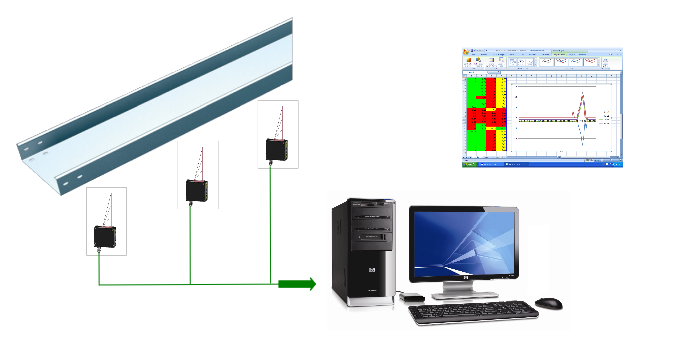

Process control on the production line

The MODULCHECK system it allows regular values to be taken from measuring instruments inserted on the production line (LASER micrometers, thermocouples, pressure and flow sensors, LASER thickness gauges). The advanced data logger function allows you to keep under control the different physical quantities involved in the production process and to generate alarms in the presence of out of tolerance. Using the EDAC acquisition modules it is possible to acquire data from different types of sensors, also physically positioned very far apart as they all the acquisition infrastructure is based on an Ethernet network.