Torque tester for caps to measure the tightening torque, both during screwing and unscrewing, of bottle caps, drums, containers, jars, bottles, receptacles and jerry cans.

Adjustable supports efficiently hold a wide range of container shapes and sizes, while optional flat and adjustable jaws are available for special profiles. The robust aluminum design and the simple and intuitive use allow the use in the laboratory and in production environments even by non-expert personnel.

High accuracy and incredibly fast sampling rate guarantee precise and reliable test results, even in fast-acting applications directly on the production line.

Product families

Torque tester for CAP-TT01 series caps

- Optional movable pegs and holders allow you to handle a wide range of sample shapes and sizes.

- Data output with associated value storage and zeroing on removal of the bottle cap help automate analysis processes.

- Password protection prevents unauthorized changes.

- The high-speed sampling rate of 7.000Hz accurately captures peak torque values.

- 5 selectable units of measure.

- Outputs USB, RS-232, Digimatic Mitutoyo and analog output.

- 1.000-point data memory with statistics and outputs.

- Set point indicators and programmable outputs for pass/fail determination.

- Configurable audio alarms.

- MESUR™ Lite data collection software included.

Torque meters for caps of small bottles

- Bidirectional accuracy of ± 1% of the indicated reading

- 8 selectable engineering units: Oz.in., Lb.in., Lb.ft., Nm, cNm, KgfCm, gfCm, Kgfm

- 3 operating modes: Track, Peak and 1st Peak

- Sturdy aluminum structure

- NiMH rechargeable batteries guarantee 8-10 hours of continuous use. Supplied with AC adapter / charger

- The lightweight and sturdy handle features multiple threaded holes with four fixing screws to fit a wide variety of containers.

- Includes NIST traceable calibration certificate

Torque meters for portable caps

- For plug diameters from 0,65 to 1,55 inches (16,5 - 39,0 mm)

- High-speed sampling rate of 2.000 Hz

- Single read USB data output

- Programmable set points with OK / NO OK indicators

- Battery operated or with external power supply

- Configurable audio alarms and key tones

- Real-time load bar graphs with set point indicators

- CE mark

- Made in the USA

- Peak memory for clockwise and counterclockwise readings saved and displayed

Technical insights

Use of torque transducers for caps

CAP-TT01 series torque transducers for caps allow the easy and precise measurement of the torque required to start or unscrew the cap of bottles, flacons, jars, tubes and jerry cans.

The measurement takes place instantly and it is possible to memorize the peak value obtained. The peak value is particularly used to check the "breakout torque" of seals or the point of maximum stress of the cap.

The high sampling frequency allows to obtain a reliable peak measurement even if the event is short-lived.

Torque measurements of bottle caps, jars, vials and vials

The TNP series digital torque meter is a precision instrument for measuring the torque values in the opening and closing of caps for various applications.

The TNP torque meter is used in the quality control of products in the industry medical, pharmaceutical, industrial, research and development and countless other torque measurement applications. As a cap torque analyzer, the TNP repeatedly determines bottle closure and breakout torque.

Its large memory capacity is capable of storing 1.000 data points, including average, maximum and minimum values. A HI-GO-LO LED comparison function can be used for large batch testing to ensure overall product quality. The TNP is a portable device powered by internal rechargeable batteries or by the supplied universal AC adapter / charger.

Designed with a small footprint, it can be easily transferred between the workshop and the laboratory taking up little space during operation. The TNP torque meter comes standard with USB connection and cable for a simple PC / Software interface. In combination with the free “DIGITORQ” software, it is possible to perform statistical tests, graphs and analyzes.

Industrial features for applications directly on the production line

The high accuracy guarantees reliable results in many industrial quality control applications.

Quick and easy installation with removable mandrel pins that adjust the size of the test diameter. The memory function allows you to conveniently store up to 1000 readings for later retrieval. One-touch operation allows for quick reset for subsequent tests.

The large, easy-to-read LCD displays torque values in four selectable engineering units. PC connectivity with USB interface and the free DIGITORQ software allows data analysis and graphical representation on Microsoft® Excel. Portable tool with a compact, lightweight design and internal rechargeable batteries Charge the batteries with the included 120/240 V AC adapter / charger or use the adapter for continuous use. Selectable measurement modes allow you to capture clockwise (CW) or counterclockwise (CCW) mean, peak opening, or peak closing values. Speed up large batch tests with the integrated red / green LED comparator that responds to pre-programmed tolerances. Durable heavy-duty die-cast aluminum construction resists wear and tear.

Characteristics of the CAP-TNP family

The accuracy of ± 0,5% FS ensures accurate and easily certifiable results.

Variety of applications met with ranges from 4,4 in-lb (50 N-cm) up to 88,5 in-lb (10 Nm).

Quick and easy setup with removable spindle pins that adjust the size of the test diameter.

The memory function allows you to conveniently store up to 1000 readings for later retrieval.

One-touch operation allows for quick reset for later tests.

The large, easy-to-read LCD displays torque values in four selectable engineering units.

PC connectivity with USB interface and free DIGITORQ software enable data analysis and graphing on Microsoft® Excel.

Truly portable with a compact and lightweight design and internal rechargeable batteries. Charge batteries with the included 120 / 240V AC adapter / charger or use the adapter for continuous use.

Selectable measurement modes allow for clockwise (CW) or counterclockwise (CCW) average, peak opening or peak closing values to be acquired.

Accelerate large batch testing with the integrated red / green LED comparator that responds to pre-programmed tolerances.

Durable, heavy-duty and wear-resistant aluminum construction.

Applications of torque transducers for caps

- Measurements on bottle caps for drinks, alcohol, water, fruit juices, milk

- Measurements on bottle caps for the pharmaceutical industry

- Measurements on caps for cosmetic products i

- Measurements on caps with safety closures for the chemical and pharmaceutical industry

- Measurements on caps for food containers both for final consumers and for the transformation industry

- Measurements on caps or products for the preservation industry (preserves, jams, long conservation)

- Measures during the production of caps and accessories (safety closures)

- Torsion measurements of taps and manual valves

- Force measurements of opening and closing of locks

Easy and practical use

The torque transducers for caps are easy to use both on the work bench on the line and in the metrological laboratory. Furthermore, the support on the table is made in a stable way and above all not influenced by the force applied to the cap during the test operations. The sturdy structure allows the test to be carried out even on large bottles and containers or with particularly large diameter caps.

Highly readable front display

The instrument display, located on the front of the instrument, allows easy reading of the measured value and the functions that have been activated. The backlighting allows viewing even in poorly lit environments or directly on the line.

External connections

On the back of the instrument there is a connector for the connection of USB peripherals, peripherals with serial ports and Digimatic. It is also possible to generate an analog signal for connection to data acquisition systems.

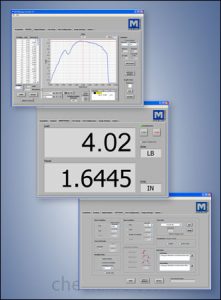

Acquisition software

Included in the supply is the MEASUR Lite acquisition software which allows the display of measurements on a PC, the acquisition of torsion curves and the recording of data in Excel format.

Accessories for TT-01 series torque transducers

Portable printer

Suitable for real-time printing of the results obtained from the measurement. With the printer it is also possible to perform statistical calculations on batches of measurements (minimum value, maximum value, average value).

The printing of the printout of the measurements in real time allows a rapid certification of the production batch.

Adapters for square bottles

The adapters for square bottles also allow the measurement of bottles and containers that do not have a cylindrical shape or that have irregular shapes. The screw adjustment allows a quick adaptation to the type change.

Adapters with adjustable jaws

Adapters with adjustable jaws allow the measurement of bottles with irregular shapes or that with standard adapters do not maintain a stable position.

The two parts in contact with the bottle are adjustable and allow perfect adaptability on containers with irregular or non-cylindrical profiles.

Weight certified for calibration

The certified weight for calibration allows you to quickly and immediately check the conditions of correct operation of the cap torque transducer.

The value found with the certified weight can be used for a periodic calibration check or for an internal certification of the instrument.

Tool fixing kit

For the use of the certified calibration weight, a fixing kit is available that allows you to position the torque transducer for caps in an optimal position for positioning the calibrator.

The fixing of the torque transducer for caps takes place on a horizontal surface, a table or a shelf.

Closing pegs

Different versions of fixing pegs with different lengths are available depending on the need to fix bottles with different heights.

Standard rungs are 31mm long. Pegs of 63 mm and 100 mm in length are also available.

Torque gauges for caps with customized jaws or made according to specific needs are available.

Calibration report

A calibration report is available on request which allows you to certify the correct functioning of the instrument.

Carrying case

A carrying case for the instrument is available.

Made of plastic material and with the inside in foam material, this case allows the transport of the torque transducer for caps in a safe way.

DataSink 100 software

If you need special software, with special acquisition functions or integrated in the management system (AS400 connection, Oracle database connection, connection with Access or MySQL), it is possible to create a customized application supplied with "turnkey" mode.

Typical values of torque

The following table shows the typical torque values for glass and plastic bottles with different types of common caps. The standard value (C) is closing, the standard value (A) is opening.

All values are expressed in Ncm

| Cap diameter (mm) | Phenolic / Urea stopper on glass bottle | Phenolic / Urea cap on plastic bottle |

| 15 | 90 (C) -45 (A) | 67 (C) -33 (A) |

| 18 | 101 (C) -56 (A) | 79 (C) -45 (A) |

| 20 | 112 (C) -56 (A) | 90 (C) -45 (A) |

| 22 | 124 (C) -67 (A) | 101 (C) -56 (A) |

| 24 | 135 (C) -67 (A) | 112 (C) -56 (A) |

| 28 | 158 (C) -79 (A) | 135 (C) -67 (A) |

| 33 | 203 (C) -101 (A) | 169 (C) -79 (A) |

| 38 | 225 (C) -112 (A) | 192 (C) -79 (A) |

| 43 | 248 (C) -124 (A) | 203 (C) -101 (A) |

| 48 | 271 (C) -158 (A) | 225 (C) -112 (A) |

| 58 | 316 (C) -158 (A) | 271 (C) -135 (A) |

| 70 | 395 (C) -203 (A) | 316 (C) -158 (A) |

| 89 | 508 (C) -248 (A) | 406 (C) -208 (A) |

| 100 | 564 (C) -282 (A) | 451 (C) -225 (A) |

| Cap diameter (mm) | PE / PP cap on glass bottle | PE / PP cap on plastic bottle |

| 15 | 135 (C) -79 (A) | 90 (C) -45 (A) |

| 18 | 146 (C) -90 (A) | 101 (C) -56 (A) |

| 20 | 169 (C) -101 (A) | 112 (C) -56 (A) |

| 22 | 192 (C) -112 (A) | 124 (C) -67 (A) |

| 24 | 203 (C) -124 (A) | 135 (C) -67 (A) |

| 28 | 237 (C) -135 (A) | 158 (C) -79 (A) |

| 33 | 271 (C) -158 (A) | 192 (C) -90 (A) |

| 38 | 327 (C) -192 (A) | 214 (C) -101 (A) |

| 43 | 372 (C) -225 (A) | 248 (C) -124 (A) |

| 48 | 293 (C) -248 (A) | 271 (C) -135 (C) |

| 58 | 497 (C) -293 (A) | 327 (C) -158 (A) |

| 70 | 587 (C) -361 (A) | 395 (C) -192 (A) |

| 89 | 734 (C) -451 (A) | 508 (C) -248 (A) |

| 100 | 847 (C) -429 (A) | 564 (C) -282 (A) |

Copyright by RODER SRL - All rights reserved - Application note AN0071