"All in one" artificial vision systems for quality control on the production line, on automatic machines and manual test benches. The new systems of the VISION CHECK 2000 series integrate a powerful artificial vision system, based on the latest generation image processing algorithms, a touch screen video interface and all the electronics necessary for interfacing with the production line or for the remote control through fieldbus or standard I / O. The powerful functions made available by the control station allow you to carry out both operations visual inspection what operations of dimensional and geometric control. The PCL2315 control station is equipped with a state-of-the-art industrial controller capable of processing the images acquired in real time, generating the response of the control in a few milliseconds. The ability to connect a very large number of cameras (up to 32 cameras), the ability to customize the lighting system and the complete configurability of the acquisition software and processing allows a very high system flexibility, guaranteeing the possibility to face all the problems of industrial control with a single artificial vision system.

Typical applications

- Vision systems for installation on production lines and automatic assembly machines.

- Vision control on robotic islands, on Cartesian manipulators or on manual test benches.

- Real-time ROBOT guidance, automatic process control, automatic machine adjustment feedback.

- Check presence / absence of parts on automatic assembly machines and check correct assembly.

- Dimensional and geometric control in the production line, verification in the metrology laboratory.

- Visual defect check and product aesthetic check.

Features

- All-in-one system that integrates acquisition, processing, visualization and control in a single control place.

- Management of up to 8 cameras with smart with PoE connection.

- Intuitive and easy to use video touch screen interface, designed for use even by untrained personnel.

- Possibility of connection with fieldbus (Profinet, EtherCAT, Modbus).

- Ethernet network connection for data exchange with management IT systems.

- Remote production recipe programming and connection with external management databases.

"All in one" artificial vision system for quality control in the production line, on automatic machines and manual test benches. The new systems of the VISION CHECK 2000 series integrate a powerful artificial vision system, based on the latest generation image processing algorithms, a touch screen video interface and all the electronics necessary for interfacing with the production line or for the remote control through fieldbus or standard I / O. The powerful functions made available by the control station allow you to carry out both operations visual inspection what operations of dimensional and geometric control. The PCL2315 control station is equipped with a state-of-the-art industrial controller capable of processing the images acquired in real time, generating the response of the control in a few milliseconds. The ability to connect a very large number of cameras (up to 32 cameras), the ability to customize the lighting system and the complete configurability of the acquisition software and processing allows a very high system flexibility, guaranteeing the possibility to face all the problems of industrial control with a single artificial vision system.

Successful cases

Dimensional control of electronic, electromechanical and mechanical parts.

Dimensional verification of diameters, thicknesses, widths and position of the components making up the assembled part. Interaxis verification with automatic calculation of the minimum, maximum and average. High speed inspection even on non-oriented parts. Integrity or aesthetic check with color discrimination and / or character recognition (OCR).

Reading of texts and numbers with verification of the validity of the text string.

Reading of symbols, characters and logos with verification of the readability of the characters or correspondence with a comparison master. Control of production and expiry dates with real-time verification of congruence with the production batch (OCR).

Integrity, position and orientation check

Verification of the integrity of labels and electronic components with control of correct positioning and orientation. Integrity or aesthetic check with color discrimination and / or character recognition (OCR). Verification of the absolute and relative position of components on PCBs and shape recognition.

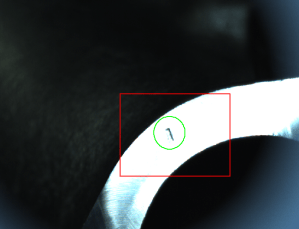

Check for defects, presence of contaminated or dents.

Check for defects, clews, dents, color change, presence of contaminants and irregularities in shape. Real-time verification on the entire surface of the product even with product in motion or subject to vibrations.

Check for surface defects or irregularities

Verification of the presence of surface defects or irregularities on the surface with identification of the distribution of defects. Real-time calculation of the size of the defect, the distribution on the surface and any anomalous concentrations of defects per unit of surface.

Dimensional and shape control and comparison with mathematical model

Dimensional and geometric control and comparison with DXF mathematical model for the determination of non-compliance areas. Extraction of the dimensional characteristics of interest and comparison with the reference mathematical model.

Identification of loose objects and verification of orientation

Position identification and orientation of loose objects or moving walkways, ROBOT guidance and control of Cartesian Pick & Place axes. Extraction of reference coordinates and angular coordinates for direct grasping with ROBOT. Recognition system with artificial intelligence combined with artificial vision.

Control and discrimination of colors

Discrimination of colors and identification of the correct coloring of objects. Multichromatic lighting for the discrimination of particular characteristics of the product or for the discrimination of the color determined by the change of contrast with the incident light. Wide choice of colors and wavelengths for comparative testing (red, green, yellow, blue, infrared, ultraviolet, white).

Profile check

Dimensional and geometric verification of the profile of mechanical parts. Extraction of the characteristic dimensions and comparison with a mathematical model or DXF drawing. Automatic calculation of widths, lengths, center distances, thicknesses and diameters.

Check position and presence of small details

Inspection of small objects through microscopes or high resolution magnification systems. Measurement systems based on high resolution cameras, low distortion optics or telescopic lenses. Micrometric checks on precision mechanical components, electronic circuits and precision assembly.

Check for scratches or visual imperfections

Check for scratches, dents, dents or visual imperfections that affect the aesthetic appearance of the final product. Control with matrix cameras or linear cameras. Real-time verification of the defect size and distribution on surface units. Applications with backlight illuminators on continuous products of large widths.

Identification of position and orientation of small parts

Identification of the position and orientation of small mechanical parts for use in automatic assembly systems. Selective inspection with determination of ROBOT gripping coordinates or automatic manipulators. Automatic orientation control with possible selection of parts that do not conform in shape and / or color.

Strengths

The control station used in the VISION CHECK 2000 series systems is built to work in an industrial environment. It is equipped with precautions and construction techniques for a long-term operating life even in harsh environments or production situations with difficult environmental characteristics.

15 inch monitor with industrial touch screen

Industrial monitor with touch screen control. High brightness and contrast. Suitable for industrial environments and for applications where high reliability and durability are required. The monitor is mounted on a stand independent of the PC and can be easily and quickly replaced in case of damage.

Fanless and Diskless architecture

The use of the most modern heat dissipation techniques allows the elimination of the cooling fans (both CPU board and internal PC). All data storage and operating system media are based on FLASH SSD. The system is therefore also protected against vibrations or mechanical stress.

LED flasher

Anomaly detector with high brightness LED flashing light. As an option it is also possible to equip the control station with an acoustic siren. The flashing light function can be customized and can manage both warning and alarm conditions.

Tilting support

Tilting mechanical support for adjusting the inclination of the monitor and the controls (possibility of being installed on a table or on a pulpit or on a shelf). Option for connection to swinging arms and overhead control pulpits.

Standard display and control interfaces

The system is based on an industrial embedded PC. So in case of temporary malfunction of the monitor or the touch you can temporarily use a keyboard, a mouse or an office monitor. This solution allows you to continue production even in the event of a temporary malfunction.

Intuitive software developed for machine operators

The software installed on the VISION CHECK 2000 has been specially developed for industrial production applications. The main functions have been collected in easy-to-read synoptics with intuitive screens that can also be managed by non-expert personnel.

Front push button

Front push-button panel for controlling the main system functions without touching the touch screen monitor (cycle start, cycle stop, fault reset, emergency). The operator can therefore also operate with gloves or in the presence of liquid contaminants. The front buttons can also house an emergency button to be connected to the central control panel of the system.

Removable SSD

Removable SSD for quick and easy commissioning in case of changes or malfunction. The embedded PC has two different SSD slots and it is possible to manage both periodic backups and duplication of running programs.

Integrated PLC

Integrated PLC for the management of local I / O signals or for the connection to existing production lines and electrical panels. Possibility to manage local command peripherals such as pedals, remote push-button panels, light towers or acoustic signaling devices.

Industrial container in painted aluminum

Painted aluminum container with safety lock for access only to authorized personnel. The container is complete with gaskets that allow the use of the control station even in particularly dusty environments or in the presence of environmental contaminants.

Industry 4.0 connectivity and performance

Ethenet connectivity

The VISION CHECK 2000 control stations can be connected to any Ethernet network system for the production data exchange, the sharing of test results, the programming of control recipes or customized reports.

Connection with EtherCAT fieldbus

The systems of the VISION CHECK 2000 family can be connected to EtherCAT fieldbus for data exchange and remote management of the synchronization operations of the vision process.

Connection with MODBUS fieldbus

The systems of the VISION CHECK 2000 family can be connected to MODBUS fieldbus for data exchange and remote management of the synchronization operations of the vision process.

High performance processors

The VISION CHECK 2000 series workstations integrate the latest generation of Intel i5 and i7 family processors. The programming of the processors takes place using the most modern multi-threading techniques on the market.

PoE connection of vision devices

All the image acquisition peripherals (matrix and linear cameras, profile sensors and LASER scanners) are powered by Power Over Ethernet or equivalent technologies. This minimizes the connection cables and facilitates maintenance or operational changes.

Connection with PROFINET fieldbus

The systems of the VISION CHECK 2000 family can be connected to PROFINET fieldbus for data exchange and remote management of the synchronization operations of the vision process.

Remote remote assistance

The systems of the VISION CHECK 2000 family can be connected remotely with the help of Team Viewer technology. The RODER support team can guarantee a quick and timely modification of the operating conditions of the system even remotely.

Windows Embedded Technology

The VISION CHECK 2000 series control stations are based on the most modern processing technologies based on Windows Embedded.

Connection to management databases

The VISION CHECK 2000 series systems can be connected to the most common management databases. The connection with company databases allows the exchange of information regarding production batches, production times, waste percentages and plant productivity indices.

High performance cameras

Matrix and linear cameras for any type of application, connectable to the Ethernet network with Power over Ethernet technology.

Resolutions up to 26 Mpx and management capacity up to 350 images per second.

Wide range of standard and telecentric lenses.

Accessories and customizations

A wide range of accessories completes the VISION CHECK 2000 series systems.

- LED illuminators for matrix cameras both in backlight and front light mode.

- LED illuminators for linear cameras both in backlight and front light mode

- Connection cables

- Optical filters and diffusers

Special customized systems

Do you need a "turnkey" system?

RODER is also able to offer and supply the complete system of customized mechanics, electrical panels, pneumatic systems and all the assistance necessary for commissioning and staff training.

Vision systems with matrix cameras e

linear. Systems, sensors and software for image analysis with latest digital cameras

generation. Versions with monochrome or color high resolution cameras in

able to perform image acquisition and processing in a few milliseconds.

Wide range of cameras, optics, filters, lighting systems, support mechanics and processing systems to meet a wide range of applications and control needs.

Integration in Industry 4.0 systems

The integration of artificial vision systems into Industry 4.0 systems is an effective way to improve the quality of products and services. Machine vision systems are able to recognize objects, analyze images and respond quickly to changes in the environment. By using them together with other technologies, such as artificial intelligence algorithms, production processes can become more efficient and precise. The result is better quality control and overall cost savings for companies.

Adding a machine vision system to an Industry 4.0 system can provide numerous benefits from both a human operator and production point of view. For example, a computer vision system can detect defects or imperfections in components that would not be noticed by the human eye, leading to greater consistency in the quality of the products produced. In addition, by automating some aspects of product assembly, labor costs can be reduced while maintaining the accuracy of manufacturing processes.

Machine vision systems also offer better safety measures when used as part of an Industry 4.0 system. Using image analysis and object recognition technology, a machine vision system can identify potential hazards that might otherwise go unnoticed by humans in the factory. This helps reduce the risks associated with accidents or injuries caused by faulty machinery or unsafe working conditions.

Implementing a machine vision system into an Industry 4.0 system requires careful planning and execution to be successful. Companies must ensure that their existing infrastructure is compatible with new technologies before attempting any integration process, as well as develop appropriate strategies for handling the data collected by these systems if they are to maximize their effectiveness in their operational environment. Additionally, it is important that these types of systems are regularly tested and maintained to ensure they continue to deliver accurate results over long periods of time.

The integration of machine vision systems into Industry 4.0 systems has the potential to revolutionize manufacturing processes in many ways, from data collection and analysis to the prevention of defective products.

With the help of advanced computer vision algorithms, companies can detect objects, measure dimensions and inspect surface defects with unprecedented accuracy. By automating inspections and quality control, companies are also able to reduce costs associated with manual labor and increase overall productivity.

When integrated into an Industry 4.0 system, machine vision technology can enable more efficient access to real-time data and analytics. This means companies can quickly assess product condition and identify areas for improvement from anywhere. Furthermore, automated inspection not only improves accuracy, but also helps prevent errors that can result from staff overload or human error in making quality control decisions.

To make sure business operations run smoothly, companies need to ensure that their machine vision systems are successfully integrated into their Industry 4.0 framework.

The system must be built using an architecture that allows for a high quality of life. The system must be built using an architecture that can accommodate all necessary input devices, such as cameras and sensors, while still being scalable enough for future upgrades or expansions. Furthermore, it is important that manufacturers choose components and algorithms that are suitable for the specific application they have in mind, as these will determine the accuracy of inspection results.

Machine vision systems offer many benefits when used in Industry 4.0, including increased accuracy in product inspections, reduced labor costs associated with manual inspections, and better access to real-time data analytics to improve decision-making skills.

Companies must ensure that their system is built correctly to take full advantage of this technology and carefully choose components to work optimally for their specific needs. By integrating computer vision technology into their existing infrastructure, companies can benefit from greater efficiency at reduced costs, while improving the safety conditions for workers involved in quality control processes, who no longer have to manually perform dangerous jobs thanks to to the automation allowed by these systems.