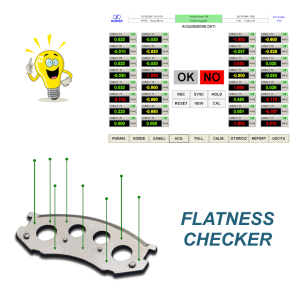

Flatness measurement on blanked parts

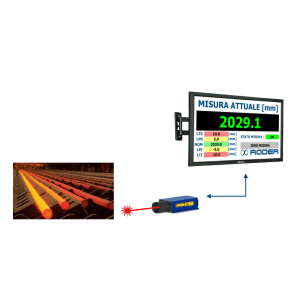

Control of defects on continuous products

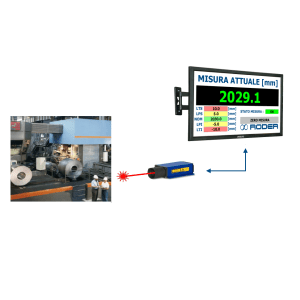

Measurement of the position of beams and pipes in line of position

Bending measurement on tube and profile benders

Application Kit for the use of LDM42 industrial LASER distance meters

Use of LASER distance meters for position and distance measurements

DM2 series LED illuminators for ROBOT guide

Radius measurement on curved furniture products

LED backlighting for vision systems

Digital radius and diameter gauge DIACHECK-CT series

Measurement of the radius of curvature with digital archimeters

Flatness measurement with multi-dimension control units and LVDT linear transducers

DL1 series LED illuminators for vision systems and optical inspection benches

Dimensional checks with multi-quota control units and LVDT linear transducers

Artificial vision systems for the control of defects on continuous products in the production line

LASER scanner for dimensional and geometric control of continuous products in the production line

Stroboscopes for speed measurement and preventive maintenance

LVDT linear transducers for dimensional and geometric control

DIACHECK measuring instruments for internal diameter measurements

SB-1000 series LASER micrometers for non-contact diameter and width measurement

Level monitoring with LASER distance meters and visualization on giant displays

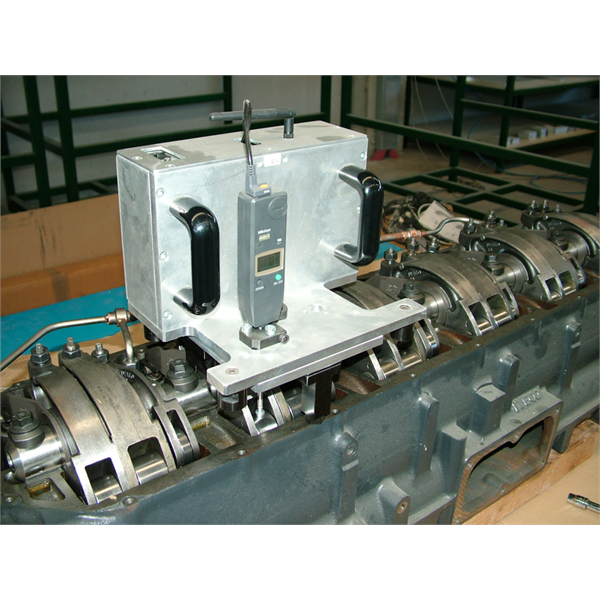

Systems for the control of the axial play of crankshafts and pulleys in internal combustion engines

Systems for the control of timing on camshafts

Systems for the control of timing and height of the top dead center in the production line

RIMAS - Robotic system for inspection, measurement and assembly of mechanical parts

Robotic islands for quality control with artificial vision systems

Automatic systems for the dimensional control of parts machined on CNC machining centers

Sorting machines for sheared, molded or CNC machined parts

Automatic equipment for dimensional and geometric control with LVDT contact probes